- Messages

- 137

I think that's what's happening, i just can't work out why the pump is running so fast to circulate water around the closest circuit to the boiler. I'm stumped  )

)

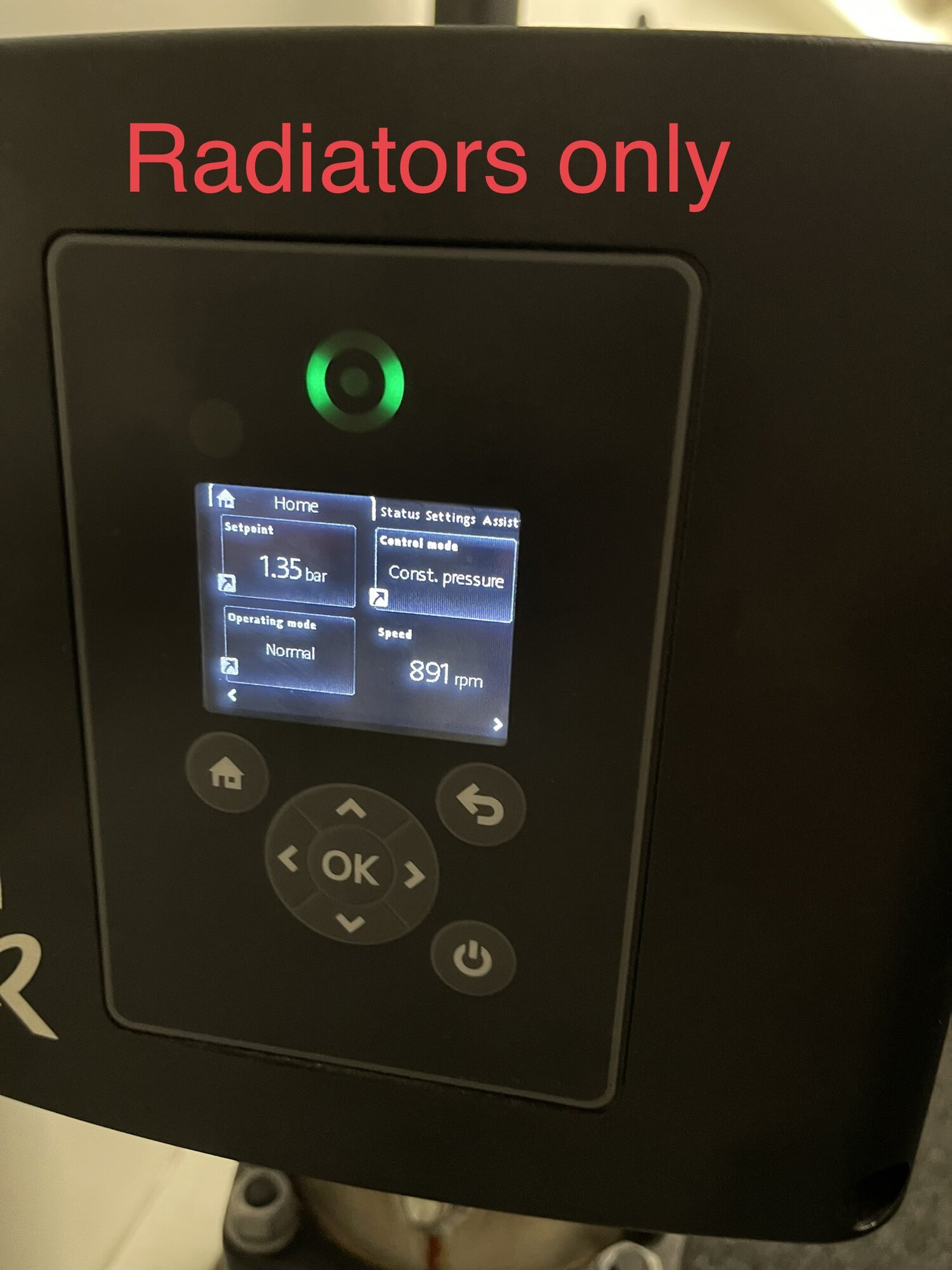

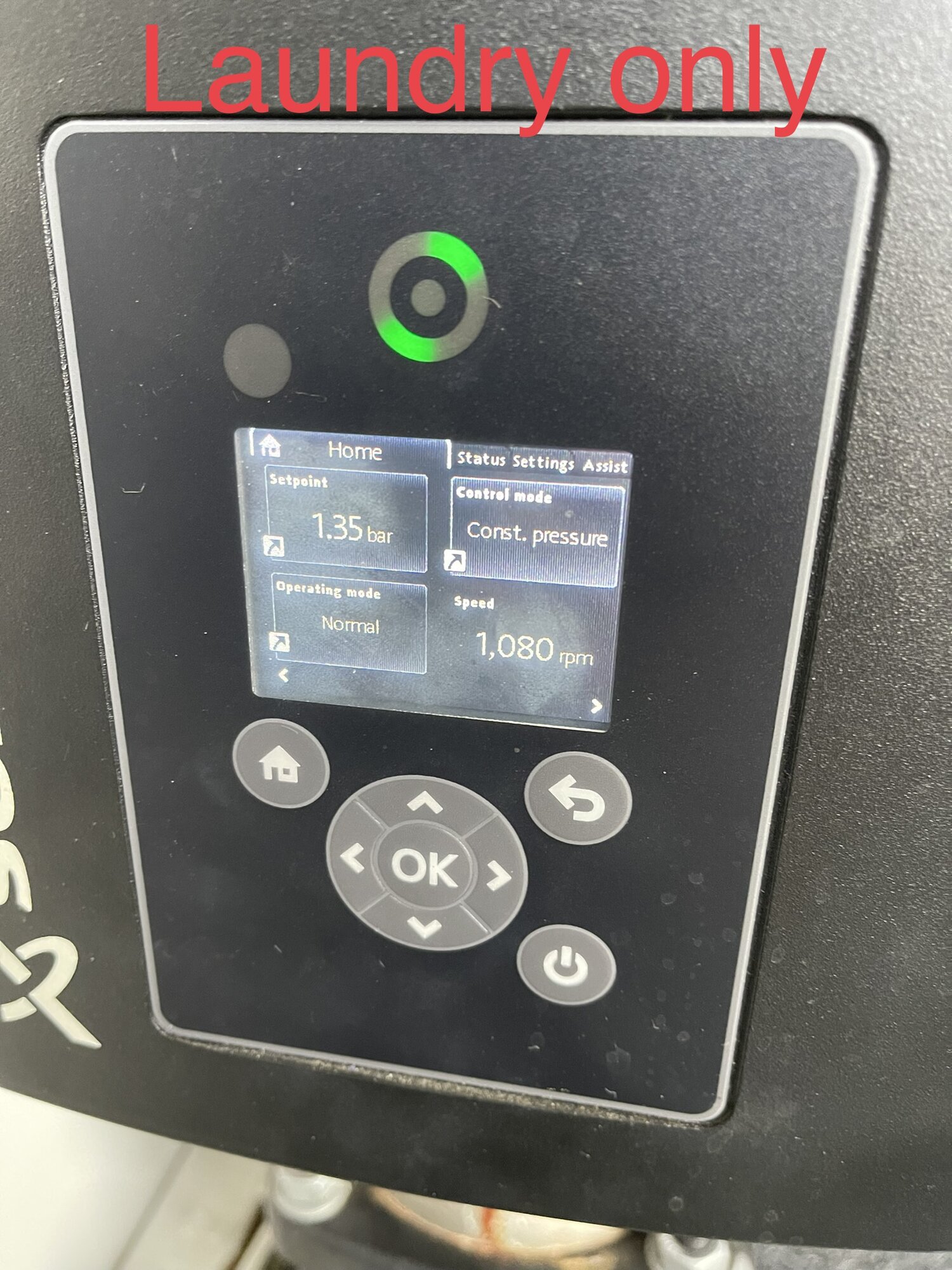

Below pics of pump operating different circuits, notice the ktichen manifold RPM compared to laundry and Radiators that have a longer circuit.

Also done an experiment with rads and kitchen (troubled manifold) both calling for heat, boiler flow never got over 43.6 degrees after 40 mins of running, i turned ufh manifold off and within 2.39 mins flow temp had risen 13.4 degrees to 57.

I am now thinking if the pump if pushing water that fast through flow to manifold is this indicating a blockage in the flow pipe?

Below pics of pump operating different circuits, notice the ktichen manifold RPM compared to laundry and Radiators that have a longer circuit.

Also done an experiment with rads and kitchen (troubled manifold) both calling for heat, boiler flow never got over 43.6 degrees after 40 mins of running, i turned ufh manifold off and within 2.39 mins flow temp had risen 13.4 degrees to 57.

I am now thinking if the pump if pushing water that fast through flow to manifold is this indicating a blockage in the flow pipe?

Its may cause erratic operation of the UFH manifold TMV because you have hot water at high pressure on one side of the TMV and much lower pressure on the other side coming from the cold manifold return.

Its may cause erratic operation of the UFH manifold TMV because you have hot water at high pressure on one side of the TMV and much lower pressure on the other side coming from the cold manifold return.