You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discuss Which is the more powerful pump? in the UK Plumbing Forum | Plumbing Advice area at PlumbersForums.net

Very good, thanks.Hi John I have been a bit busy today but will do the tests tomorrow and get the results off to you also the kw of each of the rads

The plot thickens!Hi john have checked all the pipework and everything seems to be ok in theory, there could be a "bit of a traffic jam" where the returns go back to the boiler but the only way I could alleviate that would be to incorporate swept "T"s in the return lines from the towel rails,

Can you verify/clarify the above.Hi john there are 3 rads downstairs each one on it's own drop, when I shut off the bedroom rads there was no change to the wattage :- 34 and no change to the flow :- 0.6m3/h ( both valves on each towel rail were fully open) as soon as I touched either the lockshield or the on/off valve on either towel rail the wattage went down to 22 watts and the flow went down to 0.0 m3/h it's got me thinking that there is a problem with the pipework to or from the towel rails, if I have to alter the pipe work I can get at the flow from the "Y" plan valve and increase it to 22mm (it's 15mm at the present) and take it all the way into the bedroom to where the first drop is to the big rad in the sitting room then it would be 15mm after that as I cannot get at access after that

With bedroom, Upstairs?,rads shut off, you get 34W/0.6m3/hr through the Towel rads + (maybe) the downstairs rads but if you close any one of the towel rads then 22W/0.0m3/hr.

Can or have you tried shutting the downstairs rads, opening the bedroom rads + the towel rads and note the values.

Then shut shut the towel rad(s) valves and note the values, ie with the bedroom rads only open.

Also can you see/show where the expansion vessel is tied in to the system.

A simple line diagram might show up something.

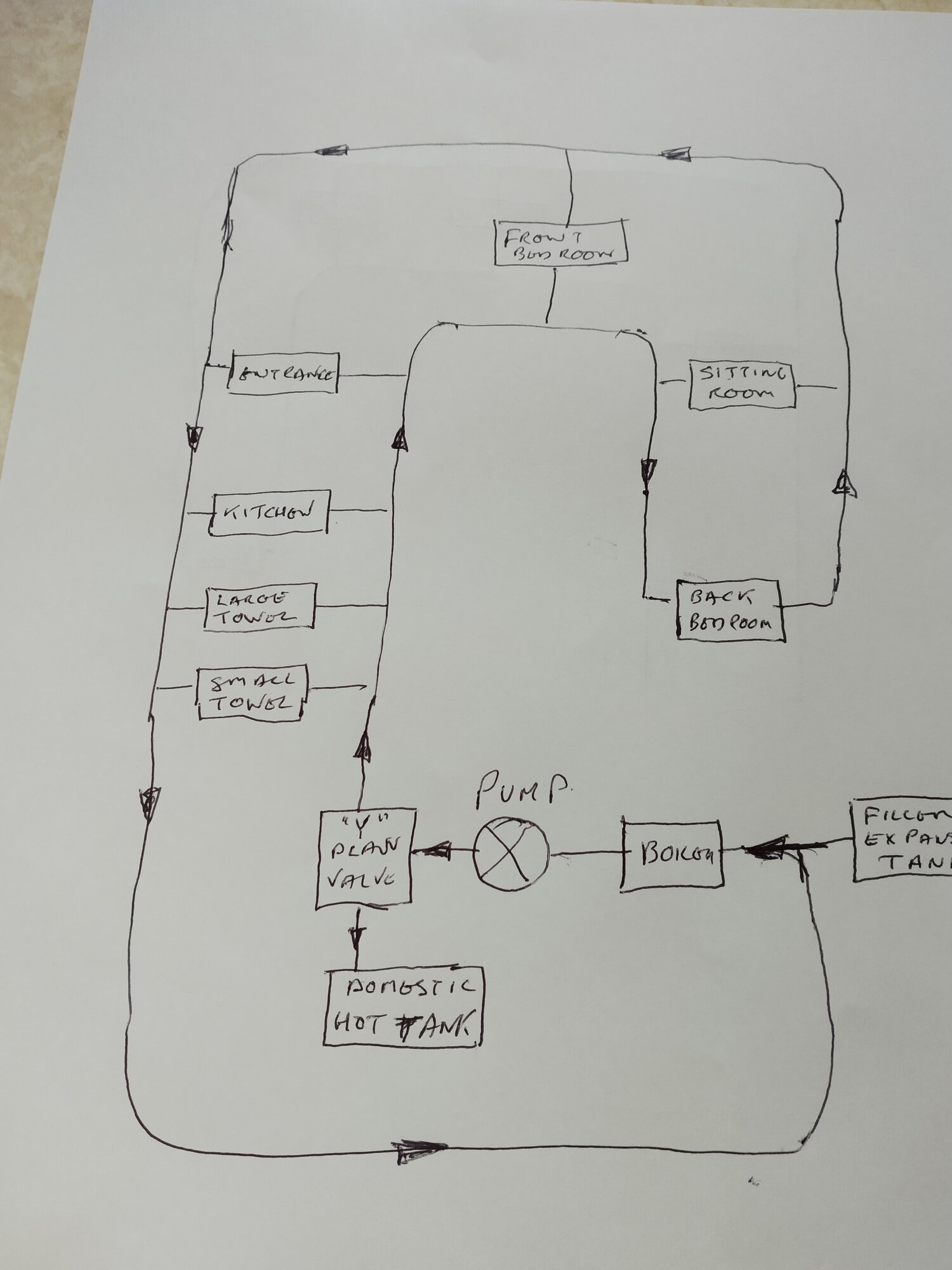

Hi John I have made a line drawing of how the towel rails are plumbed into the system as you can see theoretically it is ok, where I have ringed the drawing could possibly be a "traffic jam back to the boiler" and as I said the only way to alleviate the problem would be to replace the "T" pieces with swept "T"s ?Very good, thanks.

The plot thickens!

Can you verify/clarify the above.

With bedroom, Upstairs?,rads shut off, you get 34W/0.6m3/hr through the Towel rads + (maybe) the downstairs rads but if you close any one of the towel rads then 22W/0.0m3/hr.

Can or have you tried shutting the downstairs rads, opening the bedroom rads + the towel rads and note the values.

Then shut shut the towel rad(s) valves and note the values, ie with the bedroom rads only open.

Also can you see/show where the expansion vessel is tied in to the system.

A simple line diagram might show up something.

Hi John here are the rad output wattages :- towel rail 1700 x 700mm 668w bathroomI'll have a look at the above later on but you can see if pipework, (at least the main d/stairs flow/return) is free if you do the following before addressing the towel rad problems.

Shut off the upstairs, ensure all downstairs rads open fully, run the pump in the following 3 modes, CC3, CP1, CP2 &CP3 and note the pump values, then do the same tests with the two towel rads only and post your results, it will only take a few minutes to do these tests.

Also, please post the outputs (kw) or dimensions of the rads, including towel rads and their locations.mm

The main job is to fix your pipework and everything else can be decided then.

Edit, 3 modes are CC3, CP2 and CP3.

towel rail 600 x 550mm 221w bathroom

flat panel 1800 x 500mm 752w front bedroom

flat panel 1500 x 500mm 626w back bedroom

flat panel 1100 x 500mm 459w entrance

flat panel 1100 x500 mm 459w kitchen

double panel 2400 x 600mm 4485w

the position on the system is as follows :- small towel rail 1

large towel rail 2

kitchen 3 :- on drop

entrance 4 :- on drop

front bedroom 5

back bedroom 6

sitting room 7 :- on drop

when the system was an open vented one it had the vent running up into the loft back to the filling tank, when the plumber put in the new boiler he cut the vent in the loft and attached the expansion vessel to it, pump values to come.

What is the expansion vessel pressure and where is it displayed?, is there any pressure display on the boiler.

Does that converted vent go back to the boiler?.

Those rad outputs are incorrect in some cases a 1100X500 rad output is 1265watts and a 1500X500 is 1568watts, a 1700x700 would be roughly 2000watts.

I can figure most of them out anyhow, do they include all the house rads?.

Does that converted vent go back to the boiler?.

Those rad outputs are incorrect in some cases a 1100X500 rad output is 1265watts and a 1500X500 is 1568watts, a 1700x700 would be roughly 2000watts.

I can figure most of them out anyhow, do they include all the house rads?.

I get a total rad output of 12435W but you seem to have omitted the dining room, if you assume another double 2400X600 rad , 4485W, then the total is 16920W or say 17kw, no problem for a alpha3 as the circulation flow required is 24.4LPM @ a 10C dT and 16.2LPM @ a 15C dT. which equals pump heads of 4.2m & 5.2M respectively on CC3.

the rad outputs are as stated the outputs that you have given does relate to the values I have not watts but btu's, I take it that the expansion vessel is the red tank that is connected to the mains to fill the system, I got where it was connected wrong the vent was in fact capped off and it was connected to the feed from the filler tank, the pressure that that is showing is about 1 bar and is on a gauge on the top of the vessel there is no pressure gauge on the boiler and that is all the rads in the house.What is the expansion vessel pressure and where is it displayed?, is there any pressure display on the boiler.

Does that converted vent go back to the boiler?.

Those rad outputs are incorrect in some cases a 1100X500 rad output is 1265watts and a 1500X500 is 1568watts, a 1700x700 would be roughly 2000watts.

I can figure most of them out anyhow, do they include all the house rads?.

The values I have given are in watts, to convert to Btu, X 3.412, ie a 1800X500 single is 1881watts (you have 752W) or 6,418Btu, anyhow your total output as you have included all the rads is 12,435watts or 12.44kw so even less of a problem as the flowrates respectively now for 10C & 15C dTs are 17.83LPM & 11.89LPM.

Can you just post a photo of that E.vessel and also showing where its connected into the system, you say it is connected into the cold feed from the filler (feed & expansion) tank, so this tank is now redundant?.

OK, can you just clear this up once and for all .

If all the rads are opened up, including the towel rads, what rads heat up? (also pump values0

If all the rads are opened up, and you shut off one Towel rad , what rads now heat up? (also pump values0

If all the rads are opened up, and you close off two Towel rads, what rads now heat up? (also pump values)

Can you just post a photo of that E.vessel and also showing where its connected into the system, you say it is connected into the cold feed from the filler (feed & expansion) tank, so this tank is now redundant?.

OK, can you just clear this up once and for all .

If all the rads are opened up, including the towel rads, what rads heat up? (also pump values0

If all the rads are opened up, and you shut off one Towel rad , what rads now heat up? (also pump values0

If all the rads are opened up, and you close off two Towel rads, what rads now heat up? (also pump values)

Last edited:

in the old system ie open vented "Y" plan, the old boiler (Ferroli Roma which I put in many years ago) was fed from a small open tank in the loft and a vent from the flow went up the wall and was positioned over this small tank (this tank was removed when the new Worcester 15 Ri was put in) the old vent was cut off and capped. The old cold feed to the old boiler was cut in the loft and the expansion vessel connected to it, the expansion vessel was connected to a mains feed of 15mm dia via a pressure gauge. If all the rads and the towel rails are fully opened pump values are 34w and 0.6 m3/h and towel rads are hot, back bedroom hot, front bedroom luke warm, entrance cold, sitting room cold, kitchen just off cold. Shut off small towel rad large towel rad still hot, back bedroom hot,front bedroom flow pipe hot but rad is luke warm, entrance still cold, sitting room flow pipe hot but rad dosn't seem to be getting hot, kitchen flow pipe hot rad just off cold pump values 32w and 0.4m3/h. With both towel rails shut off the pump values are 22w and the m3/h gradually drops to 0.0m3/h . Both bedroom rads are warming up, entrance is still cold, sitting room and kitchen starting to warm up.I was wondering if there was a problem with the pump reason being I have to keep on reinstalling go remote to change the settings, also are the Alpha 3 and the Alpha2 exactly the same pump apart from how the Alpha 3 is adjusted and setup if so I was thinking of removing the head from the Alpha 3 and replacing it with the head from the Alpha 2 to see if that made any differenceThe values I have given are in watts, to convert to Btu, X 3.412, ie a 1800X500 single is 1881watts (you have 752W) or 6,418Btu, anyhow your total output as you have included all the rads is 12,435watts or 12.44kw so even less of a problem as the flowrates respectively now for 10C & 15C dTs are 17.83LPM & 11.89LPM.

Can you just post a photo of that E.vessel and also showing where its connected into the system, you say it is connected into the cold feed from the filler (feed & expansion) tank, so this tank is now redundant?.

OK, can you just clear this up once and for all .

If all the rads are opened up, including the towel rads, what rads heat up? (also pump values0

If all the rads are opened up, and you shut off one Towel rad , what rads now heat up? (also pump values0

If all the rads are opened up, and you close off two Towel rads, what rads now heat up? (also pump values)

It's amazing how the flow drops off with both T.rads shut, would wonder if any problem with system pressure...EV pipe blockage etc but as system was refilled using this then? You might just increase pressure by topping up to 1.5bar.

The pumps appear to be the same so probably OK to swap heads, but as you can easily isolate maybe easier to swap whole pump?

The pumps appear to be the same so probably OK to swap heads, but as you can easily isolate maybe easier to swap whole pump?

what would be the max pressure I could use on this system/ easier for me to just unbolt 4 bolts and swap headsIt's amazing how the flow drops off with both T.rads shut, would wonder if any problem with system pressure...EV pipe blockage etc but as system was refilled using this then? You might just increase pressure by topping up to 1.5bar.

The pumps appear to be the same so probably OK to swap heads, but as you can easily isolate maybe easier to swap whole pump?

Hi john the system used to heat up no bother with the old bathroom rad and the smaller sitting room rad so I have eliminated both of them by closing them off, if the problem was with those two items then the system should now heat up with no problems unless there is an airlock somewhere and the only way I would be able to say for definite would be to carry out flushing the system section by section, if no airlock was present then the only solution is the Alpha 3 is not doing what it is supposed to do, I can change the heads but I would not be able to say the Alpha 2 was in a working condition, but if the system heated up then it's proof the Alpha 3 is cattle trucked agreed?The boiler PRV lifts at 3bar so wouldn't,t pressurised to move than 1.5/1.7 to avoid lifting it when system heats up. Changing pump heads only gives you a opportunity to inspect impellers for sludge build up.

will let you know how I get onYes, go for that, should be a simple task, back flush from both sides when pump head removed but keep system topped up and to 1.5bar finally.

I removed the heads from both of the pumps and the size of the impellers are totally different, the Alpha 3 is only 38mm in dia where as the Alpha 2 is 63mm in dia so I am going to have to swap over the whole pumpswill let you know how I get on

Hi John I changed the pumps over and put the Alpha 2 on it's highest setting, there was no difference which makes me think (as I have not done the flushing yet) there is a blockage in the pipe line, I put my thinking cap on and came up with this, the picture that is in the attachments of the towel rail plumbing, as the towel rails were off, the system was acting as before so I opened the small towel rail and it started to get hot in no time at all, so I concluded that the flow and return for that towel rail was ok, the same applies to the large towel rail, but when I turn the towel rails off the system goes back to where it was before so I am thinking the blockage could be where the return from the front bedroom meets the return to the boiler any ideas?I removed the heads from both of the pumps and the size of the impellers are totally different, the Alpha 3 is only 38mm in dia where as the Alpha 2 is 63mm in dia so I am going to have to swap over the whole pumps

Hi John, well I cut out the "T" piece I thought might be the problem but it was ok , what was left now was an open return that was connected to that "T" so I connected a drain pipe to it, one end that was open that went to a towel rail I blanked that off, the other open end went to the boiler so I blanked that end off so I started to flush the system using the filler - expansion tank as the flow the water went through the boiler past the "Y" plan valve and into the flow pipe opened up each rad in turn and got a flow in was not very strong in fact I could stop it by putting a finger on the end of the return drain pipe, I flushed out each section in turn by opening and closing the return valves on each rad, got exactly the same flow through each section, I am going to try and put mains water pressure through the flow, by eliminating the expansion tank, boiler and "Y" plan valve and should get mains pressure back out of the return drain pipe if I do then it is as I said at the start the pumps that I have are not strong enough for my system or they are both knackered which means I need a stronger pump any ideas on these :- Britherm SL 25-80/180, Brithem super 25-120/180, Britherm Pro 2580/180, yes I know the port to port is 180 mm but that is easily overcome.Hi John I changed the pumps over and put the Alpha 2 on it's highest setting, there was no difference which makes me think (as I have not done the flushing yet) there is a blockage in the pipe line, I put my thinking cap on and came up with this, the picture that is in the attachments of the towel rail plumbing, as the towel rails were off, the system was acting as before so I opened the small towel rail and it started to get hot in no time at all, so I concluded that the flow and return for that towel rail was ok, the same applies to the large towel rail, but when I turn the towel rails off the system goes back to where it was before so I am thinking the blockage could be where the return from the front bedroom meets the return to the boiler any ideas?

Sorry for late reply, didn't get any email notification(s) of your posts.

Will read the above in more detail later.

You have a sealed system so you will have the same pressure throughout the system and it will be at the EV pressure (with allowance for elevation) so if you were to attach a pressure gauge to any part of the system then you should get 1 to 1.5bar?? pressure, makes me wonder (again) where it joins the system exactly. Unless the system is 100% blocked in places then you should feel that pressure if you hold your finger over any point of opening, if there is a blockage then yes the flow will reduce to a trickle once you remove your finger.

When you were testing/flushing, how did you keep the EV pressure at 1/1.5bar?. also whether flushing with the EV or mains, ( not a bad idea), ensure the 3 port valve is, preferably latched in CH position but if not, latch it in mid position.

I would be very surprised if any one of those two pumps is knackered, if the impellers/pump ports are clear and you are getting the power associated with the mode settings and flows, and you were, then nothing wrong there IMO.

Where does the EV outlet join the system, is it before the pump?, you might remove it where it joins the system and ensure clear.

Will read the above in more detail later.

You have a sealed system so you will have the same pressure throughout the system and it will be at the EV pressure (with allowance for elevation) so if you were to attach a pressure gauge to any part of the system then you should get 1 to 1.5bar?? pressure, makes me wonder (again) where it joins the system exactly. Unless the system is 100% blocked in places then you should feel that pressure if you hold your finger over any point of opening, if there is a blockage then yes the flow will reduce to a trickle once you remove your finger.

When you were testing/flushing, how did you keep the EV pressure at 1/1.5bar?. also whether flushing with the EV or mains, ( not a bad idea), ensure the 3 port valve is, preferably latched in CH position but if not, latch it in mid position.

I would be very surprised if any one of those two pumps is knackered, if the impellers/pump ports are clear and you are getting the power associated with the mode settings and flows, and you were, then nothing wrong there IMO.

Where does the EV outlet join the system, is it before the pump?, you might remove it where it joins the system and ensure clear.

Hi john thanks for the reply, lets start from the beginning, I bought the Alpha 2 a few years ago when I found out there was something wrong with the basic Grundfos pump, after it was fitted it was working ok, then aprox 5 years ago we replaced the old boiler with the Worcester 15 Ri again everything was fine until last year when I put in the heated towel rails, I then thought that there was something wrong with the Alpha 2 pump so I bought the Alpha 3 but that did not solve the problem, as we have tested the system thoroughly and by eliminating the towel rails the system should have heated up the same as the towel rails but it did not, I think buying a new pump at this stage is not the answer because if the system was clear the Alpha 3 should have maintained 34w and 0.6m3/h at least but it did not it went back to 22w and 0.0m3/h and the system barely got warm, so I am thinking there is a partial blockage somewhere and I think, but I could be wrong, that it is in either the flow or return between the towel rails and the first real radiator which is the kitchen because if it was past the kitchen or for that matter before the front bedroom, the kitchen rad should have got hot and the entrance but they do not, the entrance does not heat up at all, so I am going to rod the flow and return and see what happens, if they are clear then I think it is a new pumpSorry for late reply, didn't get any email notification(s) of your posts.

Will read the above in more detail later.

You have a sealed system so you will have the same pressure throughout the system and it will be at the EV pressure (with allowance for elevation) so if you were to attach a pressure gauge to any part of the system then you should get 1 to 1.5bar?? pressure, makes me wonder (again) where it joins the system exactly. Unless the system is 100% blocked in places then you should feel that pressure if you hold your finger over any point of opening, if there is a blockage then yes the flow will reduce to a trickle once you remove your finger.

When you were testing/flushing, how did you keep the EV pressure at 1/1.5bar?. also whether flushing with the EV or mains, ( not a bad idea), ensure the 3 port valve is, preferably latched in CH position but if not, latch it in mid position.

I would be very surprised if any one of those two pumps is knackered, if the impellers/pump ports are clear and you are getting the power associated with the mode settings and flows, and you were, then nothing wrong there IMO.

Where does the EV outlet join the system, is it before the pump?, you might remove it where it joins the system and ensure clear.

Can you just do up another line diagram just on that circuit including the rads, pump, 3 way valve & expansion vessel etc.

If the lines are clear then I would be almost 100% sure that a higher head pump will not sort the problem, we know (proved) that the Alpha 3 has a 6.4M head available and pumps 0.6m3/hr at this head, a 8M pump would increase the 0.6m3/hr flow to 0.67m3/hr and a 10M pump will increase the flow from 0.6m3/hr to 0.75m3/hr but neither can increase or get anything to flow where you have zero flow with a 6.4M pump head?.

If the lines are clear then I would be almost 100% sure that a higher head pump will not sort the problem, we know (proved) that the Alpha 3 has a 6.4M head available and pumps 0.6m3/hr at this head, a 8M pump would increase the 0.6m3/hr flow to 0.67m3/hr and a 10M pump will increase the flow from 0.6m3/hr to 0.75m3/hr but neither can increase or get anything to flow where you have zero flow with a 6.4M pump head?.

Hi john the line drawing is in the attachment and my way of thinking if there was a restriction in the flow after the "Y" plan valve any radiator that was prior to that restriction would heat up normally, if there was any restriction in the return line any radiator that was prior to that restriction would heat up normally, as the towel rails are both heating up and the rest of the system is just warming up or not getting warm the restriction if it was in the flow is between the towel rails and the kitchen, if it was in the return again the restriction would be between the towel rails and the kitchen, what do you think?Can you just do up another line diagram just on that circuit including the rads, pump, 3 way valve & expansion vessel etc.

If the lines are clear then I would be almost 100% sure that a higher head pump will not sort the problem, we know (proved) that the Alpha 3 has a 6.4M head available and pumps 0.6m3/hr at this head, a 8M pump would increase the 0.6m3/hr flow to 0.67m3/hr and a 10M pump will increase the flow from 0.6m3/hr to 0.75m3/hr but neither can increase or get anything to flow where you have zero flow with a 6.4M pump head?.

Attachments

That's great Ken, one picture is worth a thousand words.

From your post #80

All Rads ON 0.6m3/hr 34W

Large T.Rad Hot

Small T.rad Hot

Back B.room Hot

Front B.room L.warm

Entrance Cold

Sitting Room Cold

Kitchen Just Off Cold

Small T.rad Off, remaining Rads ON 0.4m3/hr 32W

Large T.Rad Hot

Small T.rad Off

Back B.room Hot

Front B.room L.warm

Entrance Cold

Sitting Room Cold

Kitchen Just Off Cold

Bothl T.rads Off, remaining Rads ON 0.0m3/hr 22W

Large T.Rad Off

Small T.rad Off

Back B.room warming up

Front B.room warming up

Entrance Cold

Sitting Room just about warming up

Kitchen Just about warming up

What strikes me straight away is the back bedroom, It stays Hot in the first two cases and is heating up with both T.rads off but with apparently no pump flow.

If its getting hot then that sort of proves that there is a flow through the main flow/return circuits? Can you try that Back B.room rad on only and see the pump values, if any?,

Are you sure that the isol valves on the 3 "cold" rads, Kitchen, Entrance and sitting room, are fully opened?

Flushing everywhere you can with the mains is about the most logical step now.

Your observations re restrictions make sense so running the back b.room on its own just might tell something.

From your post #80

All Rads ON 0.6m3/hr 34W

Large T.Rad Hot

Small T.rad Hot

Back B.room Hot

Front B.room L.warm

Entrance Cold

Sitting Room Cold

Kitchen Just Off Cold

Small T.rad Off, remaining Rads ON 0.4m3/hr 32W

Large T.Rad Hot

Small T.rad Off

Back B.room Hot

Front B.room L.warm

Entrance Cold

Sitting Room Cold

Kitchen Just Off Cold

Bothl T.rads Off, remaining Rads ON 0.0m3/hr 22W

Large T.Rad Off

Small T.rad Off

Back B.room warming up

Front B.room warming up

Entrance Cold

Sitting Room just about warming up

Kitchen Just about warming up

What strikes me straight away is the back bedroom, It stays Hot in the first two cases and is heating up with both T.rads off but with apparently no pump flow.

If its getting hot then that sort of proves that there is a flow through the main flow/return circuits? Can you try that Back B.room rad on only and see the pump values, if any?,

Are you sure that the isol valves on the 3 "cold" rads, Kitchen, Entrance and sitting room, are fully opened?

Flushing everywhere you can with the mains is about the most logical step now.

Your observations re restrictions make sense so running the back b.room on its own just might tell something.

Last edited:

Hi john put mains pressure to the flow after disconnection from the "Y" plan valve thus eliminating pump, boiler, "Y"plan valve and domestic hot tank, both towel rails shut off from flow, only kitchen rad fully open did get flow but as the piping to that rad is 8mm bore got a reduced flow but i would have thought that if mains pressure was going through it the water would have squirted out but it did not could stop it with light finger pressure, so I opened the back bedroom so only kitchen and back bedroom fully open flow increased but not to what I would have expected could stop it with finger pressure, which makes me think that there is a restriction somewhere in the system, to my thinking as before between towel rails and kitchen whether it's in the flow or return needs investigation, I am going to try and rod the flow and return with welding rods joined together, see what happens.That's great Ken, one picture is worth a thousand words.

From your post #80

All Rads ON 0.6m3/hr 34W

Large T.Rad Hot

Small T.rad Hot

Back B.room Hot

Front B.room L.warm

Entrance Cold

Sitting Room Cold

Kitchen Just Off Cold

Small T.rad Off, remaining Rads ON 0.4m3/hr 32W

Large T.Rad Hot

Small T.rad Off

Back B.room Hot

Front B.room L.warm

Entrance Cold

Sitting Room Cold

Kitchen Just Off Cold

Bothl T.rads Off, remaining Rads ON 0.0m3/hr 22W

Large T.Rad Off

Small T.rad Off

Back B.room warming up

Front B.room warming up

Entrance Cold

Sitting Room just about warming up

Kitchen Just about warming up

What strikes me straight away is the back bedroom, It stays Hot in the first two cases and is heating up with both T.rads off but with apparently no pump flow.

If its getting hot then that sort of proves that there is a flow through the main flow/return circuits? Can you try that Back B.room rad on only and see the pump values, if any?,

Are you sure that the isol valves on the 3 "cold" rads, Kitchen, Entrance and sitting room, are fully opened?

Flushing everywhere you can with the mains is about the most logical step now.

View attachment 77437

You certainly shouldn't be able to plug any opening with your finger doesn't matter how restricted the pipe is as the pressure will build up regardless? assuming mains pressure.

Maybe prove main piping clear first by breaking the return at the boiler and flushing through, then measure into a bucket for 30 secs or so to get the LPM, by making a educated guess at the mains pressure then can see if flowrate is ok for x meters of 15mm piping?.

Maybe prove main piping clear first by breaking the return at the boiler and flushing through, then measure into a bucket for 30 secs or so to get the LPM, by making a educated guess at the mains pressure then can see if flowrate is ok for x meters of 15mm piping?.

Last edited:

At this moment I think I have made some progress, as I said I was going to rod the pipework with 1/8 gas welding rods soldered together with a length of aprox 12-15 foot, I rodded the return which I had previously cut nothing going on there, I then cut the flow and the rod went in so far and I felt a bit of resistance so I pushed and fed the rod in further and used an in and out motion till it felt quite easy, then I connected the mains to the return opened up the furthest rad from the boiler connected a drain to the flow so that if there was anything in the system it would not flow round the system but out of the flow into the shower tray, you should have seen the amount of hard lumps of magnetite that came out, I am going to rod it again and see if any more comes out once it is clear I will reinstate the pipe work and try it, if all is clear or much improved I am thinking of getting it power flushed then fitting a magnaclean.You certainly shouldn't be able to plug any opening with your finger doesn't matter how restricted the pipe is as the pressure will build up regardless? assuming mains pressure.

Maybe prove main piping clear first by breaking the return at the boiler and flushing through, then measure into a bucket for 30 secs or so to get the LPM, by making a educated guess at the mains pressure then can see if flowrate is ok for x meters of 15mm piping?.

Hi John HURRAY sorted the rads are getting hot now just goes to show magnetite the root of all evils, rodded the flow for the second time and got a lot more out, I am going to get the system power flushed after we come back from our hols, then I am going to fit a magnaclean, obviously the heating will get better once I have balanced it, it still has the Alpha 2 pump in it, I will keep the Alpha 3 as a spare.At this moment I think I have made some progress, as I said I was going to rod the pipework with 1/8 gas welding rods soldered together with a length of aprox 12-15 foot, I rodded the return which I had previously cut nothing going on there, I then cut the flow and the rod went in so far and I felt a bit of resistance so I pushed and fed the rod in further and used an in and out motion till it felt quite easy, then I connected the mains to the return opened up the furthest rad from the boiler connected a drain to the flow so that if there was anything in the system it would not flow round the system but out of the flow into the shower tray, you should have seen the amount of hard lumps of magnetite that came out, I am going to rod it again and see if any more comes out once it is clear I will reinstate the pipe work and try it, if all is clear or much improved I am thinking of getting it power flushed then fitting a magnaclean.

Thanks for all your help much appreciated

All the best Ken

Excellent news, I will have a few extra drops of Jamesons tonight not to mention a rake of Guinness.

Does the Alpha 2 display values as well?, W (watts) will do fine. If so, when you get a chance you might run it on CP2 which is 3M and post the values, or/and any values you have just now, that will give a very good indication of how clean the system is.

What exactly does a power wash achieve that you havn't already achieved, or how does it work??. you can flush out each rad individually in your own time and add inhibitor when all is done.

Does the Alpha 2 display values as well?, W (watts) will do fine. If so, when you get a chance you might run it on CP2 which is 3M and post the values, or/and any values you have just now, that will give a very good indication of how clean the system is.

What exactly does a power wash achieve that you havn't already achieved, or how does it work??. you can flush out each rad individually in your own time and add inhibitor when all is done.

Hi John no the Alpha 2 it just has 7 different levels depending on what type of heating you have, power flushing is done by a machine that contains chemicals and uses a bigger pressure than mains pressure but at a low flow rate, when it's finished inhibitors are put in and you end up with a much cleaner system, a bit pricey but worth it, when it has been done as i said I am going to fit a magnaclean and that should prevent any new magnetite from forming.Excellent news, I will have a few extra drops of Jamesons tonight not to mention a rake of Guinness.

Does the Alpha 2 display values as well?, W (watts) will do fine. If so, when you get a chance you might run it on CP2 which is 3M and post the values, or/and any values you have just now, that will give a very good indication of how clean the system is.

What exactly does a power wash achieve that you havn't already achieved, or how does it work??. you can flush out each rad individually in your own time and add inhibitor when all is done.

Its a pity that the Alpha 2 doesn't display the power demand.

I've read some horror stories on here where presumably the system wasn't flushed out properly after this chemical clean resulting in all kinds of problems including hydrogen release, I would stay well away from it personally.

Obviously install the magfilter, try and get one that has a particulate filter as well.

I've read some horror stories on here where presumably the system wasn't flushed out properly after this chemical clean resulting in all kinds of problems including hydrogen release, I would stay well away from it personally.

Obviously install the magfilter, try and get one that has a particulate filter as well.

- Messages

- 34,353

- Solutions

- 2

Power flushing is fine just dump it afterwards

Reply to Which is the more powerful pump? in the UK Plumbing Forum | Plumbing Advice area at PlumbersForums.net

Similar plumbing topics

-

- Sticky

We have 2 brand new cordless, battery powered press tools in stock, and flying off the shelves. Our TekTools TZ1930 & TZ1550 are packed with advanced features - these cordless press tools are engineered for speed, precision, and ease of use across various applications.

Just reply to this thread...

- Replies

- 5

- Views

- 933

Hi All

I have a leak coming from within my Mira Elite QT shower. It seems to be flowing from behind the switching Control. Any ideas what could be causing this leak. Already Changed the Pump Elbow as one of the clips had popped which was causing a second small leak, Any idea? Is it time to buy...

- Replies

- 0

- Views

- 246

We are from Alberta, and I own an electrical company.

I have been asked by a BC Mechanical P. Eng. to install an emergency STOP button at the man-door to the boiler room. It's intent is to 'halt' the operation of the boilers in the room should there be an emergency. He is demanding that I do...

- Replies

- 5

- Views

- 288

We run a community village hall and have a large kitchen provided for the use of hirers. This includes a Lincat SLR9 gas cooker which I believe is a 23.8Kw appliance with all six burners and oven on max. This was installed some 10 years ago and has passed all subsequent Gas Safety inspections as...

- Replies

- 5

- Views

- 501

Hi, Can anyone advise as to why the cold water to my bathroom keeps airlocking?

This originally happened about 12 months ago and has happened 3-4 times since.

It’s an upstairs bathroom, fed from a tank in the attic. The tank is about 8 Meters away and feeds a bath, sink and toilet. The tank...

- Replies

- 9

- Views

- 375

Creating content since 2001. Untold Media.

Newest Plumbing Threads

-

Any advice for putting this shower in ?

- Started by Staggersandfalls

- Replies: 2

-

king of pipes no reply from private message

- Started by cjg

- Replies: 1

-

-

-

Why pressure gauge drop without leak

- Started by sanju pradeep

- Replies: 4

-

Hot water so hot tap and shower via our hot water tank

- Started by thecar

- Replies: 4

-

-

Running copper pipework above / across a Gas boiler?

- Started by kristeva

- Replies: 2

-

Installing pipework to avoid airlocks

- Started by Matt0029

- Replies: 1

-

DUK Pipes for thermostat shower fitted at different heights

- Started by Delforkids

- Replies: 2

-

-

-

SPorcelanosa KRION Attica screen 1.2m, anyone?

- Started by Sebastian T

- Replies: 0

-

Cistern filling one third of the way

- Started by dwaindigital

- Replies: 4

-

Boiler losing pressure only on central heating

- Started by SnosRap75

- Replies: 6