We had a plumber come to fit our concealed shower. He plumbed it in, then we fit the plasterboard and tiles. However he soon realised that he had set the shower valve body too far back into the wall so that he physically could not fit the valve handles onto the spindles because they do not protude the wall far enough. Is there anything we can do about that or do we need to break into the wall again to move the valve body??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Discuss Concealed shower advive please. in the UK Plumbing Forum | Plumbing Advice area at PlumbersForums.net

- Messages

- 3,310

Realistically, you may have a 25% chance of not having to open the wall up..

All good, plumbers insurance should pay for the repairs and he / she will cover their excess at their own expense.

Or has the tiler put too much glue behind the tiles?

Generally measure depth of tap set back from the 'supposed' face of finished tile.

This can vary on how much glue is used.

Someone will work pit who is to blame

All good, plumbers insurance should pay for the repairs and he / she will cover their excess at their own expense.

Or has the tiler put too much glue behind the tiles?

Generally measure depth of tap set back from the 'supposed' face of finished tile.

This can vary on how much glue is used.

Someone will work pit who is to blame

We fitted the plasterboard and tiles ourselves. I didn't use too much adhesive. The plumber actually admitted that he had set the valve block too far back. He has given us a refund, minus £10 that he said he used for parts, but that is nothing cost wise in comparison to what I may need to pay to get this sorted.Realistically, you may have a 25% chance of not having to open the wall up..

All good, plumbers insurance should pay for the repairs and he / she will cover their excess at their own expense.

Or has the tiler put too much glue behind the tiles?

Generally measure depth of tap set back from the 'supposed' face of finished tile.

This can vary on how much glue is used.

Someone will work pit who is to blame

- Messages

- 3,310

You have 2 options.

1/ contact supplier / manufacturer of taps and see if extensions are available...or

2/ contact plumber to rectify at their expense or get their insurance details to pay for all works required in getting the taps set to required depth.

Opening up shower walls is an expensive exercise.

Removing tiles, resetting tap depth, plastering walls, waterproofing and re-tiling and so on.

Hopefully the Plumber has insurance, because if they don't, it's probably not worth chasing them and you'll end up footing the expense.

A refund on a stuff up doesn't negate liability...particularly in your situation.

There's around 30 hours of work involved for all works necessary to repair that stuff up.

1/ contact supplier / manufacturer of taps and see if extensions are available...or

2/ contact plumber to rectify at their expense or get their insurance details to pay for all works required in getting the taps set to required depth.

Opening up shower walls is an expensive exercise.

Removing tiles, resetting tap depth, plastering walls, waterproofing and re-tiling and so on.

Hopefully the Plumber has insurance, because if they don't, it's probably not worth chasing them and you'll end up footing the expense.

A refund on a stuff up doesn't negate liability...particularly in your situation.

There's around 30 hours of work involved for all works necessary to repair that stuff up.

I don’t know the particulars of that shower but if the handles fit onto those brass bushes can’t they just be packed forwards with a spacer or washers?

In extremis get a local fabricator or a hobbyist to machine you up new brass bushes of extended length. I have done this myself on a friends lathe and my skill level is low.

In extremis get a local fabricator or a hobbyist to machine you up new brass bushes of extended length. I have done this myself on a friends lathe and my skill level is low.

We've already tried to pack it out with spacers but for some reason there's a mechanism on the middle valve handle that prevents you from doing this. Thankyou all very much for your input. I think I need to get on with the inevitable and break back into the wall. We contacted the manufacturer to see if they do extention kits, which they do not, so I don't have many options.I don’t know the particulars of that shower but if the handles fit onto those brass bushes can’t they just be packed forwards with a spacer or washers?

In extremis get a local fabricator or a hobbyist to machine you up new brass bushes of extended length. I have done this myself on a friends lathe and my skill level is low.

- Messages

- 34,333

- Solutions

- 2

stud wall ? Can’t you undo the fixings and pull the shower body forward ?

Also you look kinda screwed on the handheld I’m guessing that’s the valve in the wall ?

Also you look kinda screwed on the handheld I’m guessing that’s the valve in the wall ?

No it's a brick wall, and yes valve is in the wall.stud wall ? Can’t you undo the fixings and pull the shower body forward ?

Also you look kinda screwed on the handheld I’m guessing that’s the valve in the wall ?

- Messages

- 34,333

- Solutions

- 2

No it's a brick wall, and yes valve is in the wall.

Start chipping the tiles off sorry to say

Yep.Start chipping the tiles off sorry to say

Just sitting here thinking if I could fox this without opening walls up.

I think I could, would be difficult and not 100% certain to work, but I’d spend an hour or two trying.

The valved outlet… potentially you could get a 90 outlet with a 1/2” female connection. You could then wind it on to the valve. The valve/hole would be cover by a chrome echelon.

This obviously depends on being able to turn valve on, if it’s off and finding the correct parts. A quick google shows there are female connection outlets.

Second option would be to undo the valve, pull it out and fit a female iron on to the nut/olive in the wall. Could be possible, potentially using screwdrivers/steel rod inserted through tile hole, down the side of valve/new female iron to hold the nut while undoing/doing up. Might need to enlarge the tile hole a bit, not difficult with a 6mm diamond angle grinder bit to slowly enlarge.

Option 2.5, same as above, get valve out and using a soldering coupling, extend pipe out of tiles and fit suitable outlet. Should be enough pipe to solder to even with nut/olive left in wall. If not, use 15mm pipe, a coupling, then small bit of pipe (2mm longer than slip of above coupling, then slip coupling. Slide the above into hole and slip over pipe in wall. Once on, hit with hammer and hope the olive moves back, until enough room to solder.

The problem with the handles, doesn’t seem to difficult to resolve if you’ve got the tools/ability or are willing to pay. The below would likely be a lot cheaper than opening the walls.

Instead of trying to pack the brass spindle adapter, just extend it.

Either some sort of fitting you could screw on to the end of existing brass (using exsisting/new longer screw). This would be more difficult.

Or add an extension (same diameter as where the handle set screw tightens on existing brass) to the existing brass. This should be hollow to allow the screw to be done up. This extension should be silver soldered on to existing brass.

Could make the extension out of something like a brass 1/2” nipple. I would as I don’t have brass stock.

If you found a brass machine shop, they’d have all 3 done in an hour. My friend makes brass radiator covers etc and could easily do this.

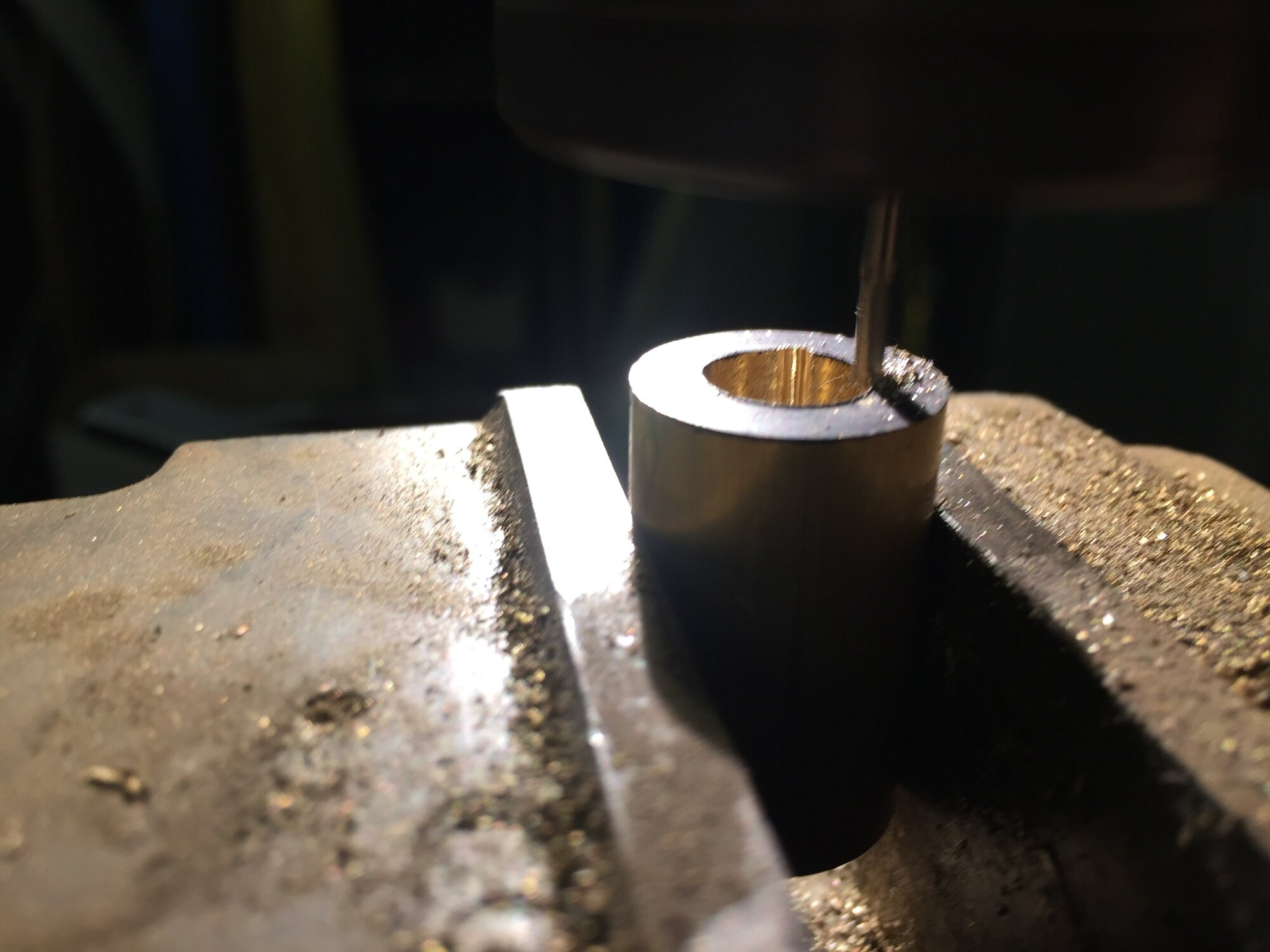

Here’s something similar I made using my mates lathe/milling machine as the apprentice lost one of the originals!

I think I could, would be difficult and not 100% certain to work, but I’d spend an hour or two trying.

The valved outlet… potentially you could get a 90 outlet with a 1/2” female connection. You could then wind it on to the valve. The valve/hole would be cover by a chrome echelon.

This obviously depends on being able to turn valve on, if it’s off and finding the correct parts. A quick google shows there are female connection outlets.

Second option would be to undo the valve, pull it out and fit a female iron on to the nut/olive in the wall. Could be possible, potentially using screwdrivers/steel rod inserted through tile hole, down the side of valve/new female iron to hold the nut while undoing/doing up. Might need to enlarge the tile hole a bit, not difficult with a 6mm diamond angle grinder bit to slowly enlarge.

Option 2.5, same as above, get valve out and using a soldering coupling, extend pipe out of tiles and fit suitable outlet. Should be enough pipe to solder to even with nut/olive left in wall. If not, use 15mm pipe, a coupling, then small bit of pipe (2mm longer than slip of above coupling, then slip coupling. Slide the above into hole and slip over pipe in wall. Once on, hit with hammer and hope the olive moves back, until enough room to solder.

The problem with the handles, doesn’t seem to difficult to resolve if you’ve got the tools/ability or are willing to pay. The below would likely be a lot cheaper than opening the walls.

Instead of trying to pack the brass spindle adapter, just extend it.

Either some sort of fitting you could screw on to the end of existing brass (using exsisting/new longer screw). This would be more difficult.

Or add an extension (same diameter as where the handle set screw tightens on existing brass) to the existing brass. This should be hollow to allow the screw to be done up. This extension should be silver soldered on to existing brass.

Could make the extension out of something like a brass 1/2” nipple. I would as I don’t have brass stock.

If you found a brass machine shop, they’d have all 3 done in an hour. My friend makes brass radiator covers etc and could easily do this.

Here’s something similar I made using my mates lathe/milling machine as the apprentice lost one of the originals!

Last edited:

I’m with Tim, and it’s easier than he thinks as there is no issue with the outlet connection!

It’s just the handles.

Like I said in post #5, this is a relatively trivial matter to fix - for someone with a metal lathe.

I would definitely go down this route rather than open up the wall - it will be far cheaper.

It’s just the handles.

Like I said in post #5, this is a relatively trivial matter to fix - for someone with a metal lathe.

I would definitely go down this route rather than open up the wall - it will be far cheaper.

Reply to Concealed shower advive please. in the UK Plumbing Forum | Plumbing Advice area at PlumbersForums.net

Similar plumbing topics

Hi all I'm hoping someone can shine a light on this for me

Since our stop tap on the pavement has now been filled with sand for whatever reason, we are relying on our property fitted stopcock (this is outside on our garage wall)

Unfortunately turning this to the closed position only reduces...

- Replies

- 3

- Views

- 243

The fittings below are for a mixer bar attached to a self contained shower. i.e not a wall. The attaching screws have snapped. I could get two new brackets, dismantle that existing one and start again or I could try and re attach via those screws, removing the broken ones from the plate and wall...

- Replies

- 1

- Views

- 195

Hi, Can anyone advise as to why the cold water to my bathroom keeps airlocking?

This originally happened about 12 months ago and has happened 3-4 times since.

It’s an upstairs bathroom, fed from a tank in the attic. The tank is about 8 Meters away and feeds a bath, sink and toilet. The tank...

- Replies

- 9

- Views

- 323

Creating content since 2001. Untold Media.

Newest Plumbing Threads

-

Pop quiz, does anyone recognise this radiator valve?

- Started by dimuc

- Replies: 1

-

SUsing coil to clear pipe leading to gutter

- Started by Sonya K

- Replies: 1

-

Replacing outdoor P-Trap Gully with Bottle Gully

- Started by DIwhYdidIstartThis

- Replies: 0

-

-

-

-

-

Mixer mixer shower, compatible with tanked supply

- Started by Matt0029

- Replies: 2

-

-

No Hot water, Fixed and Broken Again Ideal Logic 24

- Started by Filthbags

- Replies: 2

-

-

What's happening to this radiator, paint flaking off?

- Started by mikmikmikmik2024

- Replies: 3

-

Is it necessary to earth bond a Kitchen Sink?

- Started by Cello

- Replies: 6

-

Show us your fanciest radiators you have installed!!

- Started by Lou

- Replies: 4

-

Y Plan, no hot water but heating is working when called

- Started by Chopper9495

- Replies: 8