Hi there, I have the following system boiler setup with a low loss header and four different circuits. I've set the boiler flow to different levels between 65 to 70 degrees but the surface temperature readings never seem to reach much above 55 degrees into the LLH - I have tried a clip on thermometer, a wifi surface temperature and IR measurements on tape on the pipe.

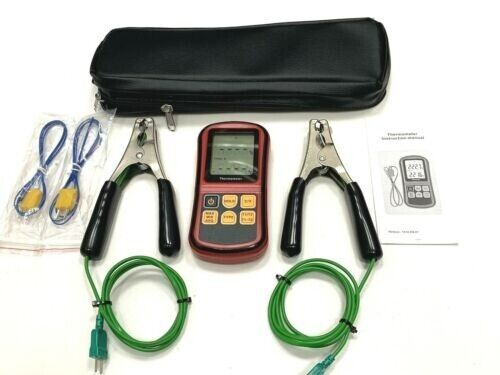

What tool can I use that would most accurately give me measurements of the temperature within the pipes, to verify the boiler is actually spitting out 65-70 degrees? I have seen some claw type products - anyone recommend an accurate one?

The radiators show around 50-55 degrees max.

Thanks for your advice

What tool can I use that would most accurately give me measurements of the temperature within the pipes, to verify the boiler is actually spitting out 65-70 degrees? I have seen some claw type products - anyone recommend an accurate one?

The radiators show around 50-55 degrees max.

Thanks for your advice