Heating issues. Had new water pump fitted 3 weeks ago, new 3 port valve 18 months ago, boiler is 4 years old. I balanced radiators when new pump was installed and for 2 weeks or so the heating and hot water worked a treat. 3 days ago, woke up to find neither working properly. Timer comes on, boiler fires up but radiators downstairs not getting warm. Hot water not great. Balanced radiators again and all was fine but last two days every time I turn heating on nothing warm downstairs in spite of balanced radiators two days ago working fine. Pump does seem to work fine when it runs quietly but each time it starts there is a whirring noise and you know it won't work properly. Any ideas?

-

NavigationPlumbing Advice Forums UK Plumbers Forums USA Plumbing Advice Australia Plumbers Talk Canada Plumbing Zone Forum Ireland Plumbing Advice

Bathrooms, Showers And Wetrooms DIY Plumbing Advice Plumbing Courses Water Underfloor Heating Advice Plumbing Tools Renewables Plumbing Zone Commercial and Industrial Plumbing Forum Specialist Plumbing Forum Oil And Solid Fuel Forum G3 Unvented Forum

Gas Engineers Advice Oil and Solid Fuel Forum Central Heating Forum Gas Engineers Forum Access-only Gas Engineers Forum G3 / Unvented

PF Community Forums Welcome Forum Plumbing News General Chat

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Currently reading:

Any ideas? Unreliable heating.

Discuss Any ideas? Unreliable heating. in the Central Heating Forum area at PlumbersForums.net

So, are you absolutely certain that the new pump is pumping in the same direction as the old one, ie, the arrow on the old pump was also pointing downwards??, Is you system as I showed above or can you post a photo of it?, its strange that you are getting problems at CP2 even though it is a bit high so CP1 may sort out the problem, was that system chemically cleaned or anything like that between pump changes?.

This is the old pump and if it appears you will see what I mean by upside down. I don't have any other image so can only presume the British gas engineer who put the new one in ensured it is pumping on same direction. No chemical cleaning I am aware of.

Well you will have to be happy (ensured) that the UPS3 is pumping in the correct direction before taking any drastic or unnecessary action, if the pipe coming out of the bottom of the pump then goes to either a three way valve or to a number of valves (all/any of which will have a motor with a cable) then pump direction is downwards, if these valve(s) come off the top pipe then the pump must pump upwards.

Yes, that's where the 3 port valve isWell you will have to be happy (ensured) that the UPS3 is pumping in the correct direction before taking any drastic or unnecessary action, if the pipe coming out of the bottom of the pump then goes to either a three way valve or to a number of valves (all/any of which will have a motor with a cable) then pump direction is downwards, if these valve(s) come off the top pipe then the pump must pump upwards.

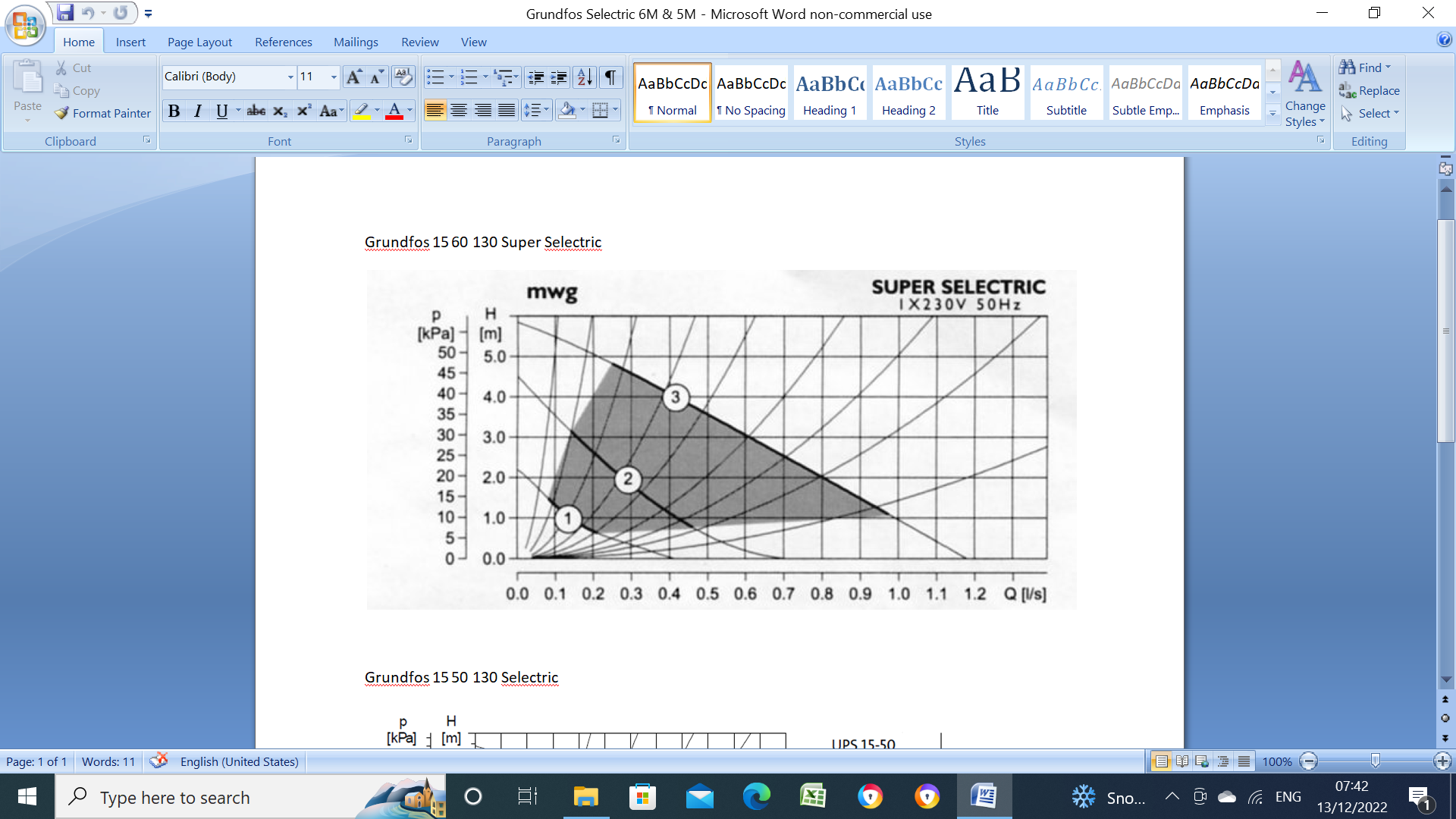

Your old pump was probably a 6M Selectric (made in 2007) so the pump curves may look like this. If so then even speed 3 has a relatively low head of 2.5m at 0.7ms/hr and hopefully CP1 or PP3 will also not cause any pumpover problems.

Last edited:

- Messages

- 1,271

CP1 is equivalent to Speed 2 on the old pump, so CP1 will probably be about right.

Gary, getting a bit confused myself re arrow on pump, can you just confirm that (if) the pump is now pumping downwards then the engineer will then have turned the head through 180 deg and the arrow will be on the right hand side of the pump body, pointing downwards.

Assuming it was how is your system performing now?.

The pump was making a very strange noise. The file I added was a video file.so 3 port below pump and pump pumping downwards is correct, CP1 or just maybe PP2 next step??

WhT was happening when the pump was stopping as can't see it

Starting from scratch tonight. Photo of setup attached showing port valve etc. Going to try CP1 following the details posted on Sunday, starting with HW ON ETC.

The arrow is downwards on the left side behind the cable socket. I can't see anything on the right hand side. Best photo I can take given the angle is here.Gary, getting a bit confused myself re arrow on pump, can you just confirm that (if) the pump is now pumping downwards then the engineer will then have turned the head through 180 deg and the arrow will be on the right hand side of the pump body, pointing downwards.

Assuming it was how is your system performing now?.

Not getting anywhere really. I had to leave heating on today as someone was home so it was on CP1 with all upstairs rads off so the living room rads were warm. The kitchen rads beyond those never really warmed up properly. Have tried to restart CP1 following the process I was asked to go through on Sunday evening but when I switch upstairs rads off there heat is not too hot downstairs with the last 2 or 3 on system almost getting nothing. Like i say I am not a plumber so have no knowledge at all but I know when it won't work just by noise of pump. When it is almost silent I know it will work but when it makes more noise it won't. I think I need to have the system cold to be able to try a proper CP1 or PP1 reset.

Got closer. Yes arrow on right is downwards.Not getting anywhere really. I had to leave heating on today as someone was home so it was on CP1 with all upstairs rads off so the living room rads were warm. The kitchen rads beyond those never really warmed up properly. Have tried to restart CP1 following the process I was asked to go through on Sunday evening but when I switch upstairs rads off there heat is not too hot downstairs with the last 2 or 3 on system almost getting nothing. Like i say I am not a plumber so have no knowledge at all but I know when it won't work just by noise of pump. When it is almost silent I know it will work but when it makes more noise it won't. I think I need to have the system cold to be able to try a proper CP1 or PP1 reset.

All inlet valves downstairs are scorching hot. All rads have been bled. First 3 rads on system downstairs are warm but there 4 after that are not.Got closer. Yes arrow on right is downwards. View attachment 80051

Very strange allright, presume not something daft like the pump valves not opened fully, they look like gate valves so should be ~ 3 or 4 full turns from fully shut to fully open. There arn't too many things left, the pump was probably changed out without drain or partial system drain down, possible sludge build up but unlikely except the F&E tank was full of crap and drained down into the system. (if system drained)

The possibility of a faulty UPS3 still exists but if so unlikely that air would continue to build up, are you still venting air, you say all rads have been bled?.

CP1 at 3M should not cause any problems and is required for most systems of your size, my system runs at 3.5/3.6M with the (Wilo) pump set to a PP setting of 4.6M.

The possibility of a faulty UPS3 still exists but if so unlikely that air would continue to build up, are you still venting air, you say all rads have been bled?.

CP1 at 3M should not cause any problems and is required for most systems of your size, my system runs at 3.5/3.6M with the (Wilo) pump set to a PP setting of 4.6M.

What does venting air mean?Very strange allright, presume not something daft like the pump valves not opened fully, they look like gate valves so should be ~ 3 or 4 full turns from fully shut to fully open. There arn't too many things left, the pump was probably changed out without drain or partial system drain down, possible sludge build up but unlikely except the F&E tank was full of crap and drained down into the system. (if system drained)

The possibility of a faulty UPS3 still exists but if so unlikely that air would continue to build up, are you still venting air, you say all rads have been bled?.

CP1 at 3M should not cause any problems and is required for most systems of your size, my system runs at 3.5/3.6M with the (Wilo) pump set to a PP setting of 4.6M.

John, should the gate valve directly under the pump be fully open? The middle of the three you can see in the photo I uploaded yesterday.What does venting air mean?

Opening the vent screws and getting rid of any air in the rads. (Bleeding the rads)What does venting air mean?

Not sure about the one with the red handwheel (you would have to trace it but let it be just now whatever its opening is).John, should the gate valve directly under the pump be fully open? The middle of the three you can see in the photo I uploaded yesterday.

The two brass valves, immediately above and below the pump MUST be fully open, get a adjustable spanner or even a pliers and try shutting first, if they are open then you should get 3 to 4 turns to shut, then immediately reopen, ie they must be ~ 3 to 4 full turns open from fully shut.

Last edited:

Cheers. In work now so will try again when I get home late afternoon.Opening the vent screws and getting rid of any air in the rads. (Bleeding the rads)

Not sure about the one with the red handwheel (you would have to trace it but let it be just now whatever its opening is).

The two brass valves, immediately above and below the pump MUST be fully open, get a adjustable spanner or even a pliers and try shutting first, if they are open then you should get 3 to 4 turns to shut, then immediately reopen, ie they must be ~ 3 to 4 full turns open from fully shut.

That middle pipe seems to go into the bottom of the immersion heater.Cheers. In work now so will try again when I get home late afternoon.

Yes, all rads are bled - doing it all the time. No air in them.Opening the vent screws and getting rid of any air in the rads. (Bleeding the rads)

Not sure about the one with the red handwheel (you would have to trace it but let it be just now whatever its opening is).

The two brass valves, immediately above and below the pump MUST be fully open, get a adjustable spanner or even a pliers and try shutting first, if they are open then you should get 3 to 4 turns to shut, then immediately reopen, ie they must be ~ 3 to 4 full turns open from fully shut.

The way I got the CP2 to work on Sunday (bleed rads, turn on HW, run HW, turn off HW, turn on CH, when upstairs rads get hot, switch them off and pump heat downstairs) is failing on the last part with CP1 as only 3 or 4 of the 7 rads downstairs get the heat - should I switch all off apart from last one and rebalance the rads?

When you bled the rads on Sunday, how much water did you bleed off each?

If no air in them then pointless venting, except that you are getting some heat in them by actually bleeding off a few litres of water which means no circulation or circ pump defective, CP2 at 4.5M even with all rads open (no balancing) should circulate plenty of water to get all/most quite hot, you have another problem IMO.

When you come home and if you find that the pump valves are fully open (and probably are) then may have to check the circ pump.

If no air in them then pointless venting, except that you are getting some heat in them by actually bleeding off a few litres of water which means no circulation or circ pump defective, CP2 at 4.5M even with all rads open (no balancing) should circulate plenty of water to get all/most quite hot, you have another problem IMO.

When you come home and if you find that the pump valves are fully open (and probably are) then may have to check the circ pump.

probably the cold water supply to your HW cylinder.That middle pipe seems to go into the bottom of the immersion heater.

Last edited:

Thanks John. I have bled the rads but not emptied them per se - when you say 'no circulation or corc pump defective' what else could cause the 'no circulation'? The weird thing is that on Sunday after I changed to CP2 all rads were hot, same Monday but then Monday night the downstairs rads went cold. So that must be an airlock? But there is no air in rads! Given that we have had heat i would guess the pump valves are fully open.If no air in them then pointless venting, except that you are getting some heat in them by actually bleeding off a few litres of water which means no circulation or circ pump defective, CP2 at 4.5M even with all rads open (no balancing) should circulate plenty of water to get all/most quite hot, you have another problem IMO.

When you come home and if you find that the pump valves are fully open (and probably are) then may have to check the circ pump.

probably the cold water supply to your HW cylinder.

last one - the screw in the pump to deblock - manual says to turn screwdriver anticlockwise, but youtube vids say ant and then clockwise? Is that a possible issue?Thanks John. I have bled the rads but not emptied them per se - when you say 'no circulation or corc pump defective' what else could cause the 'no circulation'? The weird thing is that on Sunday after I changed to CP2 all rads were hot, same Monday but then Monday night the downstairs rads went cold. So that must be an airlock? But there is no air in rads! Given that we have had heat i would guess the pump valves are fully open.

That makes sense, an airlock is a distinct possibility, the only way ("new fresh") air can get into the system is through the air vent, the pipe that bends over the F&E (small) tank. Try and tape a container of water (say a few litres) under this vent with the open end immersed in the water and watch it while starting/running the pump or as I suggested earlier on, just get someone to do as I suggested in post #15, do this first mybe.

Don't think so, if it needed deblocking anyway you should get a LED alarm.last one - the screw in the pump to deblock - manual says to turn screwdriver anticlockwise, but youtube vids say ant and then clockwise? Is that a possible issue?

- Messages

- 1,271

Turn all the rads off downstairs bar one, get that one red hot. Turn it off. Turn next one on and repeat for rest. It's just airlocking that's all by the sounds of it. If valves are red hot to radiators, then sounds like air. You've not balanced up downstairs have you?

Yes, balanced all rads up and down a few times.Turn all the rads off downstairs bar one, get that one red hot. Turn it off. Turn next one on and repeat for rest. It's just airlocking that's all by the sounds of it. If valves are red hot to radiators, then sounds like air. You've not balanced up downstairs have you?

Had a plumber come round. He has checked the pump, the valves, drained the system, rebled the system, checked the feeder tank in loft and it is still the same. He is convinced there is a blockage in the 'return' feed pipe (I am not going to pretend I know what that is) and we need to do a powerflush.

No idea sorry as I was not here. I reckon so as it was a British Gas engineer as we have the home care.Was the pump renewed without any drain down?

I don't see why anyone would drain down a system just to change out a pump, however we can talk till the cows come home but

I would go way and buy one of those cheap plug in energy monitors on amazon or where ever, remove the pump cable from the terminal box, Connect a 3 pin trailing socket into the terminal box where the pump was, put a 3 pin plug on the end of the pump cable, plug the energy monitor into the socket and plug the pump into the energy monitor and monitor the pump power, that will eliminate or not a pump problem to start with as these pumps have a very high failure rate or inconsistent performance even out of the box, the monitor is only £15 or £20 and very accurate.

I would go way and buy one of those cheap plug in energy monitors on amazon or where ever, remove the pump cable from the terminal box, Connect a 3 pin trailing socket into the terminal box where the pump was, put a 3 pin plug on the end of the pump cable, plug the energy monitor into the socket and plug the pump into the energy monitor and monitor the pump power, that will eliminate or not a pump problem to start with as these pumps have a very high failure rate or inconsistent performance even out of the box, the monitor is only £15 or £20 and very accurate.

- Messages

- 1,271

Unbalance the downstairs ones, so they're open fully. Leave upstairs balanced.Yes, balanced all rads up and down a few times.

Had a plumber come round. He has checked the pump, the valves, drained the system, rebled the system, checked the feeder tank in loft and it is still the same. He is convinced there is a blockage in the 'return' feed pipe (I am not going to pretend I know what that is) and we need to do a powerflush.

- Messages

- 1,271

I'm guessing everything worked before new Pump OK?

Reply to Any ideas? Unreliable heating. in the Central Heating Forum area at PlumbersForums.net

Similar plumbing topics

- Replies

- 0

- Views

- 109

- Replies

- 7

- Views

- 227