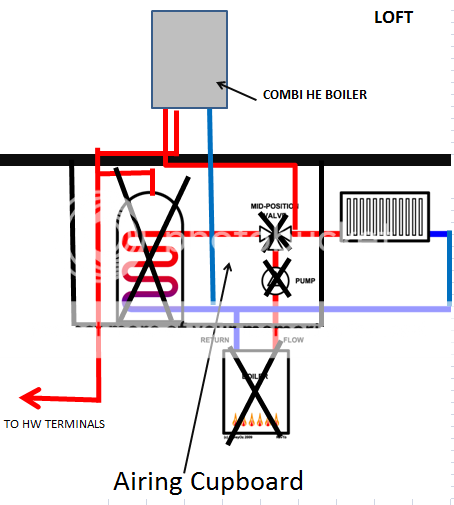

well we are taking out the tank and cylinder

mains to the tank is diverted to mains supply to boiler

hot is connected to old vent and old tee to cylinder removed

flow and return run down to cylinder cupboard,using old 22mm vent if you want for one run

link heating flow to old heating flow after removing old pump and motorised valve

link return to old cylinder return

remove boiler and cap of pipe work,make good

wall

gas run to be made in 22mm,if meter outside run up outside wall,will require to drop/loop down with isolation valve to allow gas to be isolated from below without entering loft

condensate pipe work will require running to hopefully plastic guttering or plastic soil,if problem maybe run down to old airing cupboard and into bathroom waste if next to cupboard

Power to boiler extended from airing cupboard to roof,with isolation in roof also,leaving isolation down stairs as well good idea

wireless room thermostat

ladder fixed access to roof

boarded out from opening to boiler ,with work area

as said rails around opening

cage around boiler for protection

fixed light for area

advise smoke detector

advise a pressure gauge fitted on system maybe in airing cupboard for easy checking,maybe filling loop as well fitted if mains running through old airing cupboard or maybe use old heating cold feed pipe work to bring mains down,just thoughts

all pipe work well lagged in roof space

if old wc supplied by tank,replace ball vale washers and possible inner jet

probably missed something that will be picked up to add to your check list