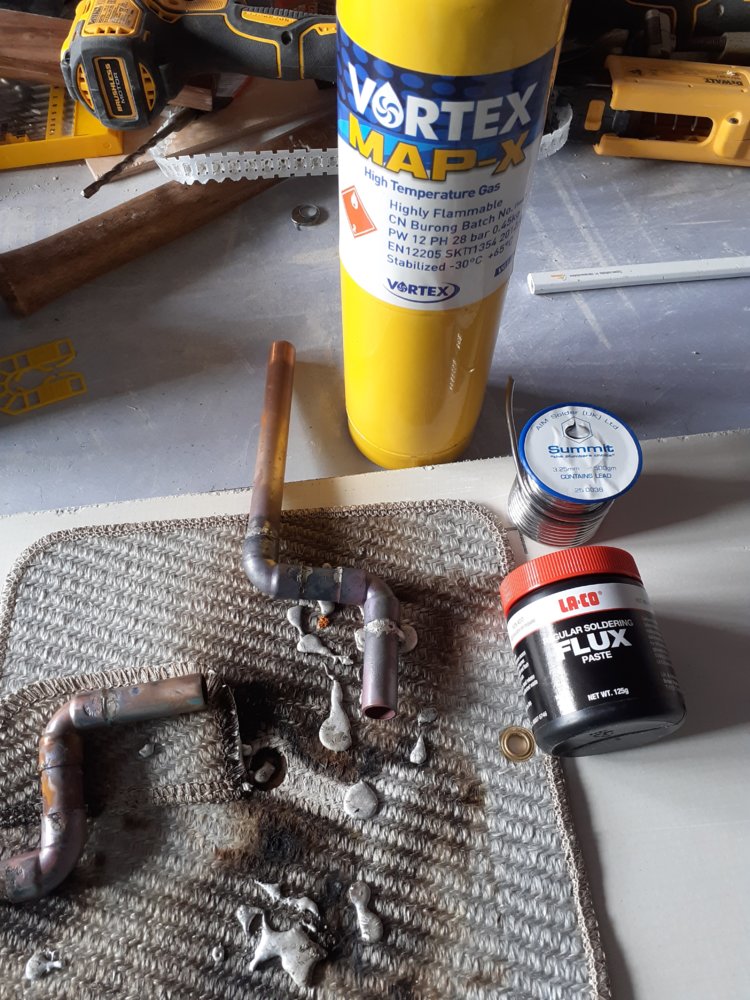

So, first plumbing job in years, bought solder, flux and MAP gas as shown.

15mm copper pipe, shined up, fluxed, absolute failure!

I'm a sparks by trade and solder a lot but not with a flame.

Am I right to assume map is far to hot for an amateur to work with, I cooked the pipe!

Advice where I'm going wrong please, I cant afford a plumber!

Cheers.

Paul.

[automerge]1587827746[/automerge]

So, first plumbing job in years, bought solder, flux and MAP gas as shown.

15mm copper pipe, shined up, fluxed, absolute failure!

I'm a sparks by trade and solder a lot but not with a flame.

Am I right to assume map is far to hot for an amateur to work with, I cooked the pipe!

Advice where I'm going wrong please, I cant afford a plumber!

Cheers.

Paul.

As a follow up, these bits are for a shower mixer, can I use JG speedfit for the link to the shower head with the supplied compression fitting or must I use a plastic fitting?

Last edited:

you can use it adjust the flame lower on your torch if possible , as for shower connection I would fit copper into the shower mixer then use a speedfit fitting to plastic . Regards kop

you can use it adjust the flame lower on your torch if possible , as for shower connection I would fit copper into the shower mixer then use a speedfit fitting to plastic . Regards kop

. Its really not that difficult to do in copper just add a few more noggings where you can screw a few brackets to, do the bracketing first clip ya copper pipes in they are easily removed for measuring a kick or set i have added a few pictures below of ones i have done how not to do aswell soldering is something that comes with practice and you really dont need loads of flux or heat clean the pipe with a cleaning pad if using brand new fitting theres no need to clean inside them , the flux only goes on the pipe a light smear is all thats needed and twist the fitting on to the pipe as you push it on swipe away the excess flux with a cloth apply a gentle heat and dab the solder on the joint when its hot enough you will see the solder run and be sucked into the joint (capillary action) always wipe the joint to clean off any runs and work tidy let it cool naturally then shine up with the cleaning pad.

. Its really not that difficult to do in copper just add a few more noggings where you can screw a few brackets to, do the bracketing first clip ya copper pipes in they are easily removed for measuring a kick or set i have added a few pictures below of ones i have done how not to do aswell soldering is something that comes with practice and you really dont need loads of flux or heat clean the pipe with a cleaning pad if using brand new fitting theres no need to clean inside them , the flux only goes on the pipe a light smear is all thats needed and twist the fitting on to the pipe as you push it on swipe away the excess flux with a cloth apply a gentle heat and dab the solder on the joint when its hot enough you will see the solder run and be sucked into the joint (capillary action) always wipe the joint to clean off any runs and work tidy let it cool naturally then shine up with the cleaning pad.