Hi All,

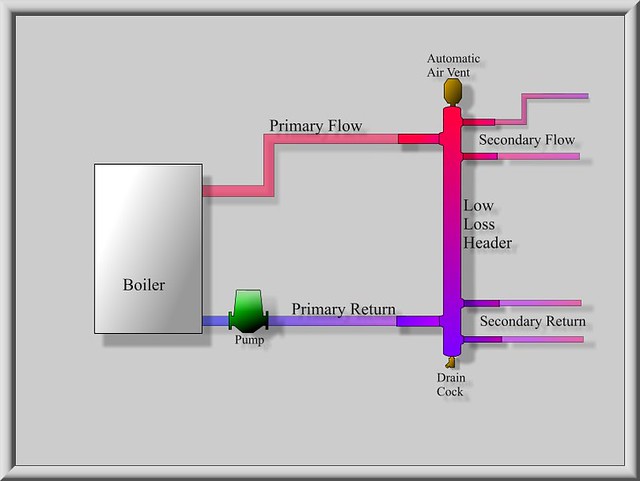

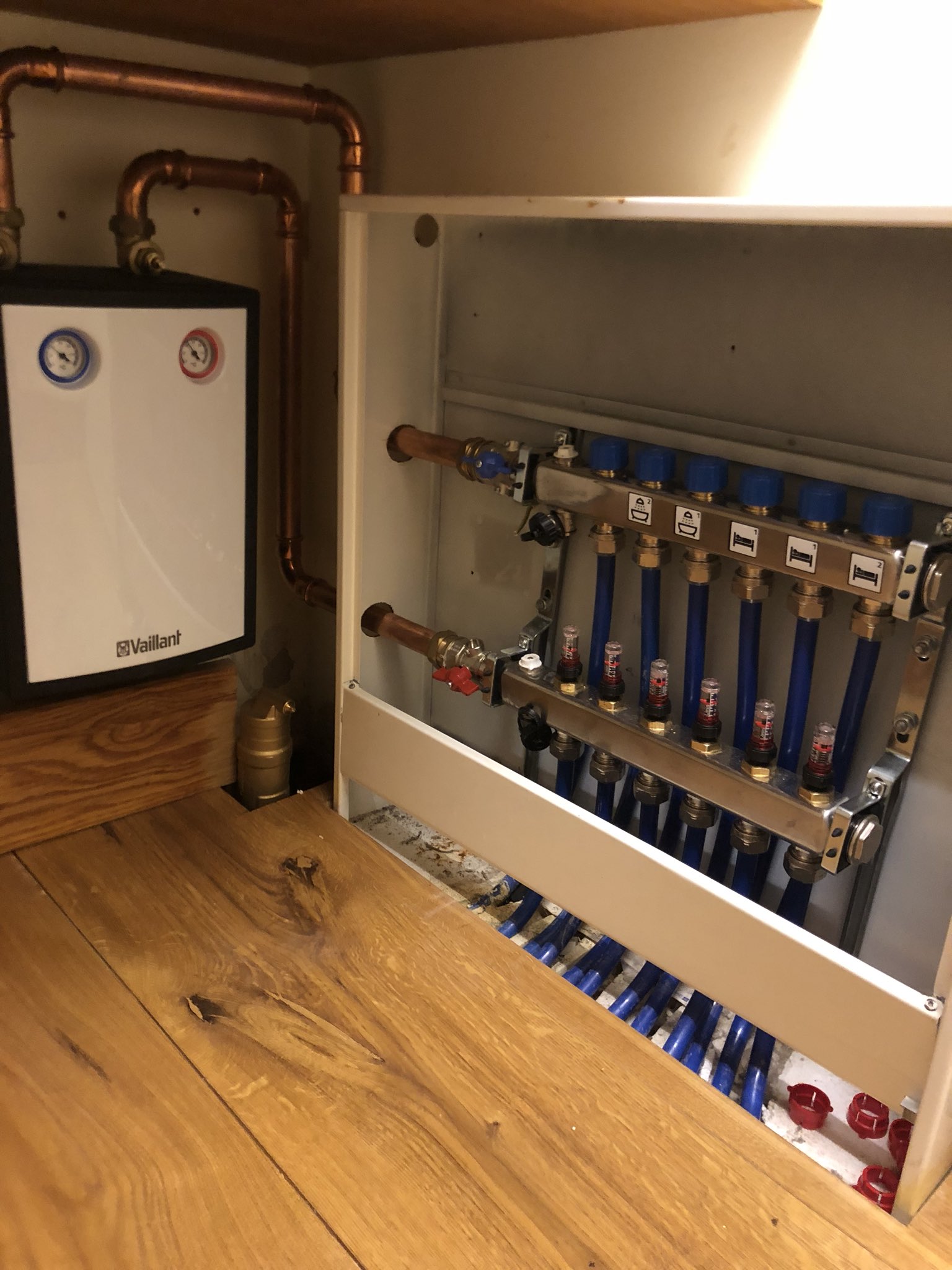

I'd like some advise regarding the installation of my boiler. Specifically the close coupled tee arangement to hookup the underfloor heating.

The boiler is currently in the loft, and is shortly moving to the ground floor.

The installation was completed by an engineer I very much trust, but he's too busy/doesnt want to travel (60miles) to me to move the boiler, so am having someone else who I also trust, but doesn't fully understand the installation, he's a bit old school, but is happy to move it "as is" to avoid any changes, and yes, he's registered.

I've had two other local engineers attend who have both slagged off the installation, but I think this is through lack of understanding. I know its not a pretty installation, it was done in the dark in an unboarded loft at the time. Once moved it can be repiped and look pretty. Which leads me onto part two of the question, attached is a diagram of how I think it would most practical to route pipework based on the new location, can anyone spot any faults with this.

The system has been in as is for about 2 years and has worked perfectly.

So...

#1 Can anyone see anything wrong with the installation as is?

#2 Can anyone see anything wrong with the drawing of how it will be?

#3 Any improvements/adjustment that could/should be made?

One bit not on the drawing, I intend to add another magnaclean or similar to the return rad feed to protect the UFH from any crap that comes from the rads.

Other details...

Boiler - Vailant EcoTec 837 Plus

Thermostat - VRC470F

Radiators - 5

UFH Loops - 4

UFH Total Area ~90SQM

UFH temp control is via flow temp sensor into the wiring centre, configured on the stat as "Heating Circuit 2", rads are on circuit 1.

Hope thats all thats required?!

Thanks in advance!

I'd like some advise regarding the installation of my boiler. Specifically the close coupled tee arangement to hookup the underfloor heating.

The boiler is currently in the loft, and is shortly moving to the ground floor.

The installation was completed by an engineer I very much trust, but he's too busy/doesnt want to travel (60miles) to me to move the boiler, so am having someone else who I also trust, but doesn't fully understand the installation, he's a bit old school, but is happy to move it "as is" to avoid any changes, and yes, he's registered.

I've had two other local engineers attend who have both slagged off the installation, but I think this is through lack of understanding. I know its not a pretty installation, it was done in the dark in an unboarded loft at the time. Once moved it can be repiped and look pretty. Which leads me onto part two of the question, attached is a diagram of how I think it would most practical to route pipework based on the new location, can anyone spot any faults with this.

The system has been in as is for about 2 years and has worked perfectly.

So...

#1 Can anyone see anything wrong with the installation as is?

#2 Can anyone see anything wrong with the drawing of how it will be?

#3 Any improvements/adjustment that could/should be made?

One bit not on the drawing, I intend to add another magnaclean or similar to the return rad feed to protect the UFH from any crap that comes from the rads.

Other details...

Boiler - Vailant EcoTec 837 Plus

Thermostat - VRC470F

Radiators - 5

UFH Loops - 4

UFH Total Area ~90SQM

UFH temp control is via flow temp sensor into the wiring centre, configured on the stat as "Heating Circuit 2", rads are on circuit 1.

Hope thats all thats required?!

Thanks in advance!