You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Thread starter Savdefriz

- Start date

- Replies 52

- Views 7K

- heating mixing pressure problems underfloor underfloor heating

Discuss Mixing Pressure Problems in the Central Heating Forum area at PlumbersForums.net

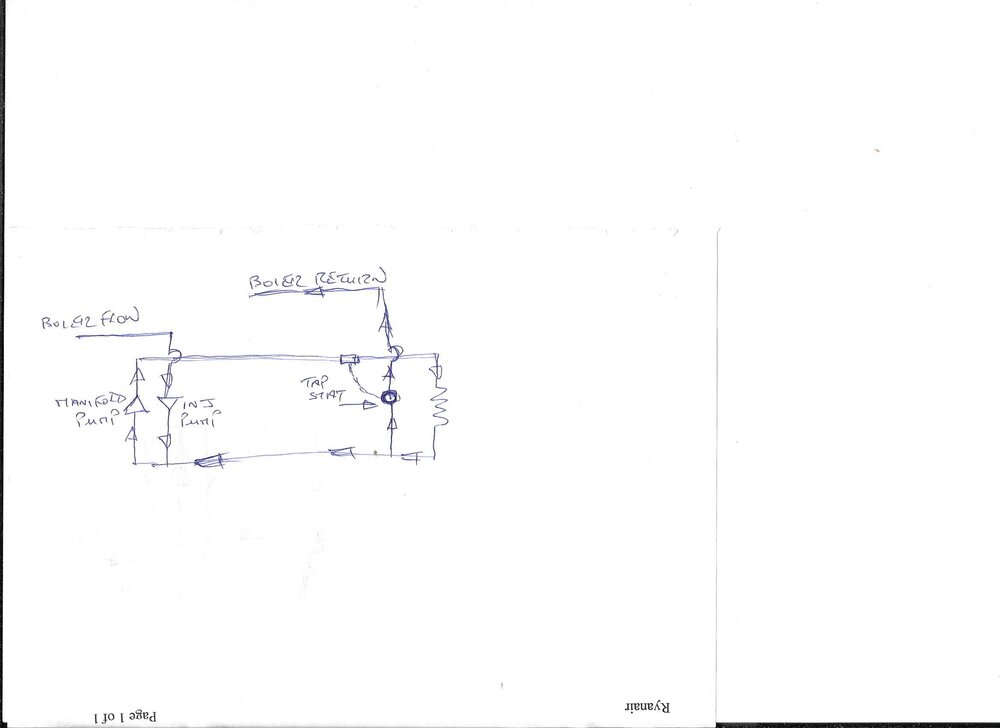

Just putting on my magicians hat but i think this will probably work.

Remove the return loop as there is no more risk of the boiler having insufficient flow with this proposal than with the pump/blender route.

So, remove return loop, leave existing by pass as is.(shut)

install new return piping Teed as far upstream as possible on the cold return and connect into the return to the boiler at the now broken loop with isol v/vs at both ends.

Install tapstat (injector valve) in this piping and connect sensor to the mixed water line or the cold water return as required.

I think this has a good chance of working as the hot water will be taken in by the manifold pump and the cold water return by the boiler circ pump via the controlling injection valve.?

You might even be able to run with no injection pump if on UFH only

The attachment shows the injector pump pumping into the manifold discharge unlike this set up.

Remove the return loop as there is no more risk of the boiler having insufficient flow with this proposal than with the pump/blender route.

So, remove return loop, leave existing by pass as is.(shut)

install new return piping Teed as far upstream as possible on the cold return and connect into the return to the boiler at the now broken loop with isol v/vs at both ends.

Install tapstat (injector valve) in this piping and connect sensor to the mixed water line or the cold water return as required.

I think this has a good chance of working as the hot water will be taken in by the manifold pump and the cold water return by the boiler circ pump via the controlling injection valve.?

You might even be able to run with no injection pump if on UFH only

The attachment shows the injector pump pumping into the manifold discharge unlike this set up.

Last edited:

I was thinking that this might be the simplest fix. Just cut the bypass pipe, loop it out and put a t junction back in to the pipe pretty much directly above where it is at the moment. That will mean greater distance between the injector and the bypass returning the cold, meaning that less cold should flow back. I've left the Grundfos on (I) and the mix is heating up but it's a really big system (I think there's about 1600m of underfloor piping in the house). I'm hoping now that the answer might just be as simple as put the pump on a lower setting!

[automerge]1606938550[/automerge]

Glad that you've enjoyed the Craic... You may be right, but I'm never going to get that sorted before Christmas! I feel like I'm getting somewhere but as I said to John earlier, everything in this system is nonstandard and I'm just a man with no knowledge of plumbing trying to figure it all. Let's just say that if I was putting this in from scratch I probably would have chosen something a little more "standard". I'll invite everyone to come and have a look once things get back to normal!!!!I've watched this thread with interest im still sure only real cure is in essence to convert manifolds to standard pump/blender layout its done that way because it works!.

If its what you want flow temperatures double what our achieving would be possible

Last edited:

IMO, whatever else, you will definitely have to break the link between the flow and return.

Why don't you just switch off that injection pump just now and see if any improvement, there should be sufficient head from the boiler circ pump, the water will still flow through the stopped injection pump and it will now not tend to pull cold water back into the system.

Why don't you just switch off that injection pump just now and see if any improvement, there should be sufficient head from the boiler circ pump, the water will still flow through the stopped injection pump and it will now not tend to pull cold water back into the system.

You have too many UFH circuits to feed to have any chance of an unconventional system to work well - unless you know exactly what you are doing. The UFH circuits take a high percentage of the boiler output - they need to be fed directly from the boiler - with the radiator and Dhw circuit in parallel.

The concept of using pumps for “injection” on low temperature heating systems is common in the world of thermal stores, but you need temperature sensors properly located and a control system to drive the pump. From what I can see on your photos, the pump you refer to as an injector is not plumbed in correctly and does not appear to have a temperature control loop or a limiting device to set or limit the flow temperature into the UFH loops. You don’t want 60 plus degree boiler flow temperatures entering the UFH loops.

On a system such as yours, the feed for the UFH circulation should come direct from the boiler to a pumped manifold with a mixing valve - relatively cheap and it will work.

If you had one or two UFH loops you may get it to work in an uncontrolled manner by tweeking it.

The concept of using pumps for “injection” on low temperature heating systems is common in the world of thermal stores, but you need temperature sensors properly located and a control system to drive the pump. From what I can see on your photos, the pump you refer to as an injector is not plumbed in correctly and does not appear to have a temperature control loop or a limiting device to set or limit the flow temperature into the UFH loops. You don’t want 60 plus degree boiler flow temperatures entering the UFH loops.

On a system such as yours, the feed for the UFH circulation should come direct from the boiler to a pumped manifold with a mixing valve - relatively cheap and it will work.

If you had one or two UFH loops you may get it to work in an uncontrolled manner by tweeking it.

You have too many UFH circuits to feed to have any chance of an unconventional system to work well - unless you know exactly what you are doing. The UFH circuits take a high percentage of the boiler output - they need to be fed directly from the boiler - with the radiator and Dhw circuit in parallel.

The concept of using pumps for “injection” on low temperature heating systems is common in the world of thermal stores, but you need temperature sensors properly located and a control system to drive the pump. From what I can see on your photos, the pump you refer to as an injector is not plumbed in correctly and does not appear to have a temperature control loop or a limiting device to set or limit the flow temperature into the UFH loops. You don’t want 60 plus degree boiler flow temperatures entering the UFH loops.

On a system such as yours, the feed for the UFH circulation should come direct from the boiler to a pumped manifold with a mixing valve - relatively cheap and it will work.

If you had one or two UFH loops you may get it to work in an uncontrolled manner by tweeking it.

The system does have thermocouples and a control system. There is a temperature sensor for the boiler feed, and a temperature sensor for the mix. The injection pump is supposedly controlled by the processing unit to control the flow of water into the UFH system so that the temperature of the mix is appropriate to the outdoor conditions (which is measured by a third thermocouple on the north facing wall). It's just that the pressure on the UFH is hard to balance and I don't know enough about a Grundfos Alpha 2L to know what I'm doing!

[automerge]1606946589[/automerge]

[automerge]1606946732[/automerge]The system does have thermocouples and a control system. There is a temperature sensor for the boiler feed, and a temperature sensor for the mix. The injection pump is supposedly controlled by the processing unit to control the flow of water into the UFH system so that the temperature of the mix is appropriate to the outdoor conditions (which is measured by a third thermocouple on the north facing wall). It's just that the pressure on the UFH is hard to balance and I don't know enough about a Grundfos Alpha 2L to know what I'm doing!

The bluebox on the wall is a kanmor 361e controller.The system does have thermocouples and a control system. There is a temperature sensor for the boiler feed, and a temperature sensor for the mix. The injection pump is supposedly controlled by the processing unit to control the flow of water into the UFH system so that the temperature of the mix is appropriate to the outdoor conditions (which is measured by a third thermocouple on the north facing wall). It's just that the pressure on the UFH is hard to balance and I don't know enough about a Grundfos Alpha 2L to know what I'm doing!

[automerge]1606946589[/automerge]

Attachments

I am very familiar with Kanmor and the 361 - it does not (nor is it intended) to control the UFH flow temperature. For that you need a wax operated mixing valve.

The Kanmor 361 is intended to inject hot water from a controlled (known temperature balanced source ( plus or minus 8 degrees )) - and that is a thermal store not a direct fired boiler. The Kanmor has no capability to accept a return temperature so cannot adjust to any feedback from a fluctuating flow temperature.

The external temperature sensor feeds directly to the boiler and adjusts the flow temperature against a preset curve ( which you can adjust) - it has nothing to do with the performance on the UFH - it only adjusts the boiler flow temperature, it does not adjust mix - it has no control loop to do that.

It operates on what is known as proportional bounded adjustment - it takes the feed temperature and then applies a preset reduction to feed the UFH

Be very careful with an UFH if you have expensive floor coverings - you don’t need many (upward) temperature excursions to cause damage to engineered wood or fabric covered floors

The Kanmor 361 is intended to inject hot water from a controlled (known temperature balanced source ( plus or minus 8 degrees )) - and that is a thermal store not a direct fired boiler. The Kanmor has no capability to accept a return temperature so cannot adjust to any feedback from a fluctuating flow temperature.

The external temperature sensor feeds directly to the boiler and adjusts the flow temperature against a preset curve ( which you can adjust) - it has nothing to do with the performance on the UFH - it only adjusts the boiler flow temperature, it does not adjust mix - it has no control loop to do that.

It operates on what is known as proportional bounded adjustment - it takes the feed temperature and then applies a preset reduction to feed the UFH

Be very careful with an UFH if you have expensive floor coverings - you don’t need many (upward) temperature excursions to cause damage to engineered wood or fabric covered floors

Last edited:

I'll bow to your greater knowledge, but my system does look like the one that I found in the manual.

tekmar 361 Mixing Control - Manual (Page 4) - https://www.manualsdir.com/manuals/594646/tekmar-361-mixing-control.html?page=4

Temp has dipped to 30 at the mo but not too worried as DHW has just been on for kids baths. The house feels a bit better, but there's a lot of concrete that needs heating so I'm not expecting to see any significant rises for days (if I'm lucky enough to get any at all)

tekmar 361 Mixing Control - Manual (Page 4) - https://www.manualsdir.com/manuals/594646/tekmar-361-mixing-control.html?page=4

Temp has dipped to 30 at the mo but not too worried as DHW has just been on for kids baths. The house feels a bit better, but there's a lot of concrete that needs heating so I'm not expecting to see any significant rises for days (if I'm lucky enough to get any at all)

can you just feel the pipe just to the left of the T for the injection pump, it should be very hot....at boiler temperature, now feel the pipe on the inlet to the inj pump.....that too should be at the same temperature, if not and only lukewarm (30C) then you are simply pulling in cold water from the by pass and the system will never work, you have a good chance if you break the flow/return loop.

I don't know enough about this stuff but I'm learning. Here's the schematic of my system from the book. (Although I've no radiators). As I said I'm just a science teacher trying to warm up his house.I will say no more. Look at the schematic on page 1 of the manual on the link you have posted.

That is not the system you have shown in your photos. Also note the inputs ( 3 no to the controller) and then reread my earlier posting

[automerge]1606950944[/automerge]

Pipe to the left is hot, injector pipe is hot, pipe to the right is hot but cools once it gets to the relay. Pump is hot and temp is rising again.can you just feel the pipe just to the left of the T for the injection pump, it should be very hot....at boiler temperature, now feel the pipe on the inlet to the inj pump...that too should be at the same temperature, if not and only lukewarm (30C) then you are simply pulling in cold water from the by pass and the system will never work, you have a good chance if you break the flow/return loop.

[automerge]1606951046[/automerge]

Pipe to the left is hot, injector pipe is hot, pipe to the right is hot but cools once it gets to the relay. Pump is hot and temp is rising again. I've got pump set to lowest setting which seems to help.can you just feel the pipe just to the left of the T for the injection pump, it should be very hot....at boiler temperature, now feel the pipe on the inlet to the inj pump...that too should be at the same temperature, if not and only lukewarm (30C) then you are simply pulling in cold water from the by pass and the system will never work, you have a good chance if you break the flow/return loop.

[automerge]1606951163[/automerge]

Even the pipe directly under the pump feels hot..... Oooohhhh such excitementI don't know enough about this stuff but I'm learning. Here's the schematic of my system from the book. (Although I've no radiators). As I said I'm just a science teacher trying to warm up his house.

[automerge]1606950944[/automerge]

Pipe to the left is hot, injector pipe is hot, pipe to the right is hot but cools once it gets to the relay. Pump is hot and temp is rising again.

[automerge]1606951046[/automerge]

Pipe to the left is hot, injector pipe is hot, pipe to the right is hot but cools once it gets to the relay. Pump is hot and temp is rising again. I've got pump set to lowest setting which seems to help.

Attachments

Last edited:

Cycling. It seems to kick in to push the temp up then falls back. I think it's kicking in when the boiler temp sensor falls below about 52. It pushes it up to about 72 and switches off.Didn't realize you had no rads so if no demand for HW then is the boiler running constantly now or cycling on/off?.

[automerge]1606953174[/automerge]

Now it seems to be constant..... I need to spend less time with my boiler and more with my wife!Cycling. It seems to kick in to push the temp up then falls back. I think it's kicking in when the boiler temp sensor falls below about 52. It pushes it up to about 72 and switches off.

Last edited:

OK, thanks.

Picasso has had a good drop of Jamesons tonight so sketching not up to his usual standard but this is the way I would go if you don't want to modify to a 3 way thermostatic mixer, there isn't much involved, as I said previously, you can leave the existing by pass if you wish (less work)

and just do the other changes.

and just do the other changes.

Picasso has had a good drop of Jamesons tonight so sketching not up to his usual standard but this is the way I would go if you don't want to modify to a 3 way thermostatic mixer, there isn't much involved, as I said previously, you can leave the existing by pass if you wish (less work)

Looks good, the only downside to that would be that (from what I've read) the system would be less efficient as the control system wouldn't be able to regulate temp. But at this point in time I'd take an inefficient system that works over an efficient cold one that doesn't.... I'll keep you up to date with temps as they fluctuate, and have a drop for me!OK, thanks.

Picasso has had a good drop of Jamesons tonight so sketching not up to his usual standard but this is the way I would go if you don't want to modify to a 3 way thermostatic mixer, there isn't much involved, as I said previously, you can leave the existing by pass if you wish (less work) View attachment 46533and just do the other changes.

I wonder just how sophisticated UFH systems really need to be as the system is a big thermal store in itself and runs 24/7, so very slow to respond to any tweeking, also your boiler will be running with a very low return temperature (no rads) so will be quite efficient.

Even though I would like to see if the proposed mods will work I think the sensible way to go would be with a 3 way thermostatic mixing valve as you will be making pipework changes anyway and will just re use the existing manifold pump.

Even though I would like to see if the proposed mods will work I think the sensible way to go would be with a 3 way thermostatic mixing valve as you will be making pipework changes anyway and will just re use the existing manifold pump.

Excellent, the trick now is to try to figure out what is the heat input into your UFH to heat your house, don't know the Baxi heat output but whatever it is, it is more than likely that it can modulate down to 5 or 6 kw which in turn means that it should certainly just now ( 1C here in Cork) be running continuously to have any meaningful contribution to heating the house, is it?.

It seems to be working of sorts. I think that the system is possibly too big and the flow of water too low to heat the house properly. I can get the rooms up to 21/22 but the circulating hot water never gets above 35. I suppose that this makes it more efficient, but it can't cope with sudden changes in temp! I managed to get the pressure balanced by a bit of trial and error, but I'm seriously thinking of buying myself a thermal imaging device so that I can see what's really going on!Any update on the above?.

Reply to Mixing Pressure Problems in the Central Heating Forum area at PlumbersForums.net

Similar plumbing topics

- Question

Ideal Logic 24, Previous problem was that the hot water was only cold or barely warm if the heating was in use. If heating was off and boiler cold then would get hot water most of the time. Changing the flow cartridge about 2 years ago (when I moved in) solved this problem enough to suffer it as...

- Replies

- 1

- Views

- 75

Every two weeks or so I have to go and top up the system because the hot taps are running cold. Boiler display is flashing 0.6 bar and I fill up to 1.3. I've had an engineer look inside the boiler and he can't see anything wrong. I've checked the pipes all over the house and cannot see any...

- Replies

- 1

- Views

- 89

Hello plumbers in my internet. So the Mrs want a spray mixer tap in the kitchen as we had two separate taps. I changed the tap for a temporary two hole mixer but the cold water pressure is high mains fed and the hot is low pressure immersion tank fed. I've been trying to find info on what I...

- Replies

- 0

- Views

- 53

Hi, Can anyone advise as to why the cold water to my bathroom keeps airlocking?

This originally happened about 12 months ago and has happened 3-4 times since.

It’s an upstairs bathroom, fed from a tank in the attic. The tank is about 8 Meters away and feeds a bath, sink and toilet. The tank...

- Replies

- 9

- Views

- 300

Hi all I'm hoping someone can shine a light on this for me

Since our stop tap on the pavement has now been filled with sand for whatever reason, we are relying on our property fitted stopcock (this is outside on our garage wall)

Unfortunately turning this to the closed position only reduces...

- Replies

- 3

- Views

- 229

Creating content since 2001. Untold Media.

Newest Plumbing Threads

-

-

Mixer mixer shower, compatible with tanked supply

- Started by Matt0029

- Replies: 2

-

-

No Hot water, Fixed and Broken Again Ideal Logic 24

- Started by Filthbags

- Replies: 1

-

-

What's happening to this radiator, paint flaking off?

- Started by mikmikmikmik2024

- Replies: 2

-

Is it necessary to earth bond a Kitchen Sink?

- Started by Cello

- Replies: 4

-

Show us your fanciest radiators you have installed!!

- Started by Lou

- Replies: 0

-

Y Plan, no hot water but heating is working when called

- Started by Chopper9495

- Replies: 8

-

-

Towel Rail Valve Advice please (35 Characters needed.)

- Started by NorthernLad

- Replies: 7

-

Unvented discharge at high level current regs

- Started by Matt0029

- Replies: 11

-

Trying to source a dual-flush valve

- Started by Thomas J Marshall

- Replies: 2

-

-