Hello all and Merry Christmas,

We are in the process of planning the replacement of our 50-year old heating boiler serving a residential block of 12 flats with a total of 60 radiators. It is a vented single-pipe heating system, which has not been properly maintained, and we only recently installed a commercial magnetic filter to filter out as much sludge as we can prior to the replacement. We will be installing a 100kw boiler. I know that we could also install two 50kw boilers, but this is a matter for a different post. A heat exchanger will protect the new boiler from the old vented system. Our installer suggested that we use the following pool heat exchanger, because it has 2 inch connections matching our 2 inch pipes and also has larger waterways so that it does not get clogged.

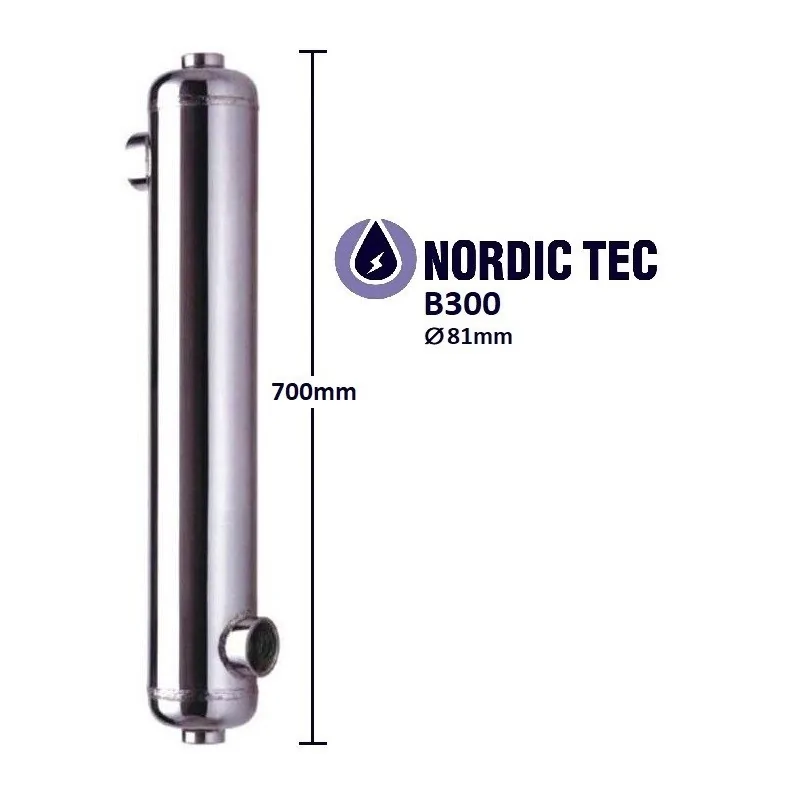

POOL HEAT EXCHANGER NORDIC B300 88KW (300KBTU/H)

Pool Heat Exchanger NORDIC B300 88kW (300kBTU/h) - https://nordictec-store.com/b-line-pool-heat-exchangers/171-pool-heat-exchanger-nordic-b300-88kw-300kbtuh.html

How suitable is this pool heat exchanger for our purposes? I am concerned that it may not be as efficient as a normal heat exchanger. Also, the suggested heat exchanger is 88kw, yet the new boiler will be 100kW.

I can order a normal heat exchanger with 2 inch connectors and to address the clogging issue I could use a CMX inline filter like this one here from Addey: MagnaClean CMX® | ADEY - https://www.adey.com/product/magnaclean-cmx The medium and large models can also be used inline.

I would appreciate your feedback.

Below is information for the pool heat exchanger:

POOL HEAT EXCHANGER NORDIC B300 88KW (300KBTU/H): €319.99 VAT included

Pool&Spa Heat Exchanger B300

Nordic Tec B-Serie

Nominal Capacity: 88kW

based on 60 °C difference between heating and heated medium (water to water),

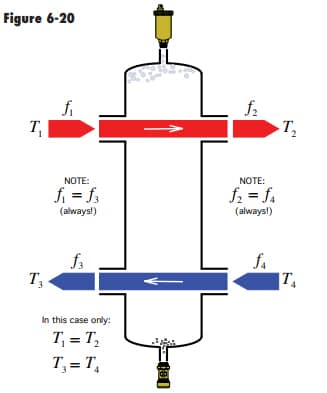

with counter-courent work

Material: Stainless steel 316L

Heat Exchange surface: 0.64 m²

Connections: 2x 2" & 2x 1 1/2"

Important Note: If one of media is glicol, the capacity will be only 85-90% of nominal one

Pool&Spa Heat Exchanger B300

Nordic Tec B-Serie

Technical Details:

Nominal value 88kW (power/capacity) is based on 60 °C difference

between heating water and pool water (calculations are different for other media).

If there is other temperature difference, the capacity is following:

60 °C = 100%

50 °C = 85%

40 °C = 70%

30 °C = 55%

The nominal flowrates values are also required to achieve the declared capacity.

Nominal flowrates: 42/325 l/min (one of opportunities)

nordictec-store.com

nordictec-store.com

We are in the process of planning the replacement of our 50-year old heating boiler serving a residential block of 12 flats with a total of 60 radiators. It is a vented single-pipe heating system, which has not been properly maintained, and we only recently installed a commercial magnetic filter to filter out as much sludge as we can prior to the replacement. We will be installing a 100kw boiler. I know that we could also install two 50kw boilers, but this is a matter for a different post. A heat exchanger will protect the new boiler from the old vented system. Our installer suggested that we use the following pool heat exchanger, because it has 2 inch connections matching our 2 inch pipes and also has larger waterways so that it does not get clogged.

POOL HEAT EXCHANGER NORDIC B300 88KW (300KBTU/H)

Pool Heat Exchanger NORDIC B300 88kW (300kBTU/h) - https://nordictec-store.com/b-line-pool-heat-exchangers/171-pool-heat-exchanger-nordic-b300-88kw-300kbtuh.html

How suitable is this pool heat exchanger for our purposes? I am concerned that it may not be as efficient as a normal heat exchanger. Also, the suggested heat exchanger is 88kw, yet the new boiler will be 100kW.

I can order a normal heat exchanger with 2 inch connectors and to address the clogging issue I could use a CMX inline filter like this one here from Addey: MagnaClean CMX® | ADEY - https://www.adey.com/product/magnaclean-cmx The medium and large models can also be used inline.

I would appreciate your feedback.

Below is information for the pool heat exchanger:

POOL HEAT EXCHANGER NORDIC B300 88KW (300KBTU/H): €319.99 VAT included

Pool&Spa Heat Exchanger B300

Nordic Tec B-Serie

Nominal Capacity: 88kW

based on 60 °C difference between heating and heated medium (water to water),

with counter-courent work

Material: Stainless steel 316L

Heat Exchange surface: 0.64 m²

Connections: 2x 2" & 2x 1 1/2"

Important Note: If one of media is glicol, the capacity will be only 85-90% of nominal one

Pool&Spa Heat Exchanger B300

Nordic Tec B-Serie

Technical Details:

Nominal value 88kW (power/capacity) is based on 60 °C difference

between heating water and pool water (calculations are different for other media).

If there is other temperature difference, the capacity is following:

60 °C = 100%

50 °C = 85%

40 °C = 70%

30 °C = 55%

The nominal flowrates values are also required to achieve the declared capacity.

Nominal flowrates: 42/325 l/min (one of opportunities)

Pool Heat Exchanger NORDIC Tec B300 88kW ( 300 kBTU/h )

Swimming pool heat exchanger B300 90 kW- full catalogue of pool heat exchangers by Nordic Tec with quick delivery in every European country.