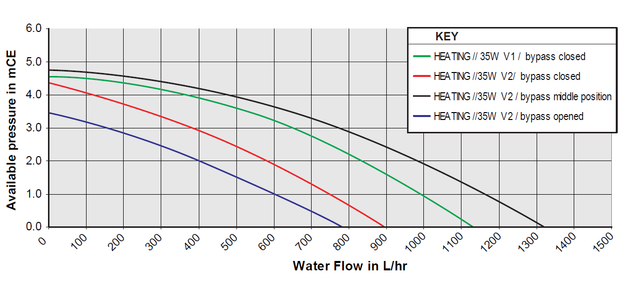

This pump curve is from a combi boiler with an internal automatic bypass valve.

Why is the maximum flow obtained with the bypass valve in the middle position? Shouldn't a fully closed bypass valve result in a higher flow through the main circuit?

Also, any idea what 'V1' and 'V2' mean (no clues in the boiler manual)?

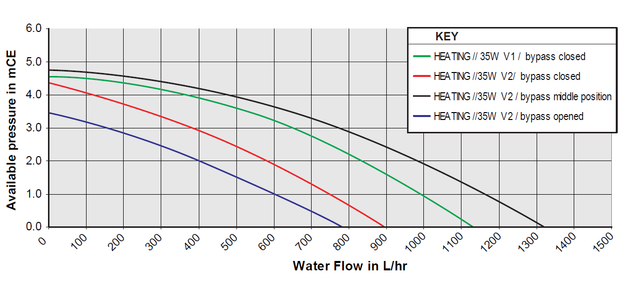

Why is the maximum flow obtained with the bypass valve in the middle position? Shouldn't a fully closed bypass valve result in a higher flow through the main circuit?

Also, any idea what 'V1' and 'V2' mean (no clues in the boiler manual)?