- Messages

- 7

I need some help from the internet before I waste any more time and money trying to fix air getting in to my central heating! Looking for advise on what to do next, as the 3 plumbers I've used so far haven't been much use. Down in East London, near Romford for what it's worth!

Issue summary:

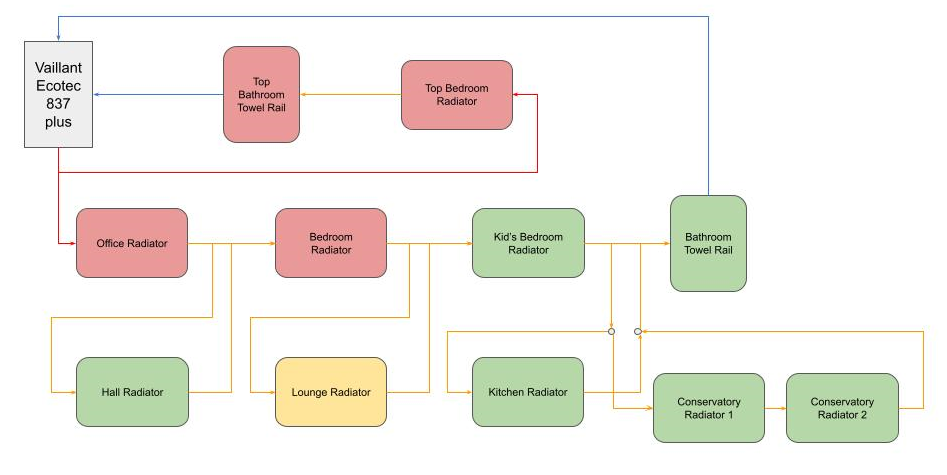

I think this is roughly how the plumbing is - hard to tell as I haven't lifted all the floors. Laid out as ground floor, first, second.

Things tried (in rough order) to stop the noise:

Help please!

Issue summary:

- Boiler is a Vaillant ecotec 837 plus, I imagine over 10 years old (we've only been here 6 years). Heating set to 70 degrees. It's in the loft conversion (so top of the house).

- All radiators get hot, but the red radiators (See diagram below) are affected by the sound of noise air passing through the valves. Air accumulates but isn’t hydrogen (passes the flame test). Most of the piping is copper, except the loft conversion.

- The downstairs yellow radiator makes a gurgling noise but air doesn’t get to it. Isn’t airlocked - gets hot.

- If all / most of the TRVs are open, then the rads are basically quiet as you would expect. During the day, it's likely that just 3 radiators are on (Office, + 2 in the conservatory).

- I noticed last week that you can hear (what I assume is) kettling in the boiler. I was under the impression that kettling didn’t produce significant amounts of air in the system. Maybe air being pulled in somewhere else and passing through the system?

I think this is roughly how the plumbing is - hard to tell as I haven't lifted all the floors. Laid out as ground floor, first, second.

Things tried (in rough order) to stop the noise:

- All radiators and TRVs replaced in the last 6 years

- Boiler serviced annually, currently no leaks, magnaclean cleaned (and never particularly bad after 12 months)

- Replaced a leaking diverter valve in 2019; plumber speculated it was damaged by the particles flying around the central heating.

- Power flushed in November 2020 after towel rail / last rad replaced. Used chemicals, they went around banging the rads, added inhibitor afterwards

- Got the AAV replaced in March 2021 out of desperation during a service (thought air might be being sucked in. We removed a piece of scale or rust lodged in the pump impellor too.

- Have tried the various pump speeds in the service menu (no change)

- Last plumber adjusting the diverter value (no change)

- I’ve gone around and checked for any leaks in rads / visible piping. Pinched a couple of nuts.

- Got a sieve fitted on the return feed, incase the powerflush somehow missed particles making noise. Came out empty after a few weeks though so I’ll probably remove the sieve insert at some point.

- Last time I checked, pressure is~1.5bar at 32 degrees C, ~1.9 at 70 degrees. Doesn’t appear to fluctuate significantly. Not many opportunities to recheck the pressure at cold temp now it’s winter.

Help please!