- Messages

- 27

Hello there!

I hope your weekend has started well.

TL/DR: Should I replace 90-degree bend with a smaller type to increase the fall from the shower tray?

I am replacing a bathtub with a 1500 X 800 Sonas shower tray which I will place on 4-inch blocks, probably with some 18mm marine ply on top. The shower will be a thermostatic one with two outlets that can be used at the same time, fed with a 2-bar universal ST pump.

The problem is the waste pipe for the old bath is solvent welded so I can't undo the fittings (I am new to this). Also, I am concerned about getting enough of a fall from the shower tray to the waste pipe, although the distance is only about 3 feet.

Could I cut away the existing 90-degree waste pipe bend at floor level (concrete floor so no access below, it's an apartment building) and replace it with a 90-degree bend like the one shown in this image? Would this drastically reduce the flow rate as the lower end of the 90-degree bend must be smaller than the current one?

Here are some more photos that give more info.

Above: The current waste pipe leading to the hole in the concrete floor. The fall is impacted by the type of 90-degree bend used for the old bath.

Above: The existing solvent welded pipe. It connects to the 4-inch waste stack below the concrete level.

Above: My vernier calipers tells me the existing pipe is 43mm, but that's probably a standard 40mm pipe.

I will be fitting a 1500mm X 800mm slate shower tray with a fast-flow waste.

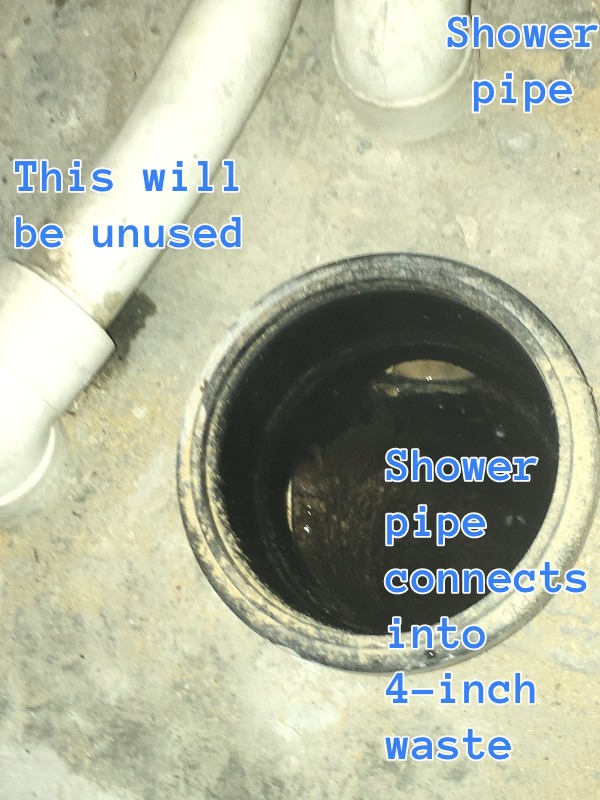

Above: This shows how the pipes connect below the concrete level. There is another waste pipe too (was for the basin waste) but it protrudes onto the floor too much so I plan to blank it off and connect the basin waste into the shower waste, probably.

This seems like a small thing but if I get it wrong my fancy new shower won't work properly. My 2-bar ST Monsoon pump will be pumping water into a regular shower head and rain shower head at the same time so there could be a lot of water flowing. Would reducing the size of the lower end of that 90-degree bend reduce the flow capacity enough to be a problem? How would you tackle this?

As always, your help is greatly appreciated!

Dave

I hope your weekend has started well.

TL/DR: Should I replace 90-degree bend with a smaller type to increase the fall from the shower tray?

I am replacing a bathtub with a 1500 X 800 Sonas shower tray which I will place on 4-inch blocks, probably with some 18mm marine ply on top. The shower will be a thermostatic one with two outlets that can be used at the same time, fed with a 2-bar universal ST pump.

The problem is the waste pipe for the old bath is solvent welded so I can't undo the fittings (I am new to this). Also, I am concerned about getting enough of a fall from the shower tray to the waste pipe, although the distance is only about 3 feet.

Could I cut away the existing 90-degree waste pipe bend at floor level (concrete floor so no access below, it's an apartment building) and replace it with a 90-degree bend like the one shown in this image? Would this drastically reduce the flow rate as the lower end of the 90-degree bend must be smaller than the current one?

Here are some more photos that give more info.

Above: The current waste pipe leading to the hole in the concrete floor. The fall is impacted by the type of 90-degree bend used for the old bath.

Above: The existing solvent welded pipe. It connects to the 4-inch waste stack below the concrete level.

Above: My vernier calipers tells me the existing pipe is 43mm, but that's probably a standard 40mm pipe.

I will be fitting a 1500mm X 800mm slate shower tray with a fast-flow waste.

Above: This shows how the pipes connect below the concrete level. There is another waste pipe too (was for the basin waste) but it protrudes onto the floor too much so I plan to blank it off and connect the basin waste into the shower waste, probably.

This seems like a small thing but if I get it wrong my fancy new shower won't work properly. My 2-bar ST Monsoon pump will be pumping water into a regular shower head and rain shower head at the same time so there could be a lot of water flowing. Would reducing the size of the lower end of that 90-degree bend reduce the flow capacity enough to be a problem? How would you tackle this?

As always, your help is greatly appreciated!

Dave